With the wind energy sector rapidly gaining momentum in Australia and internationally, many more wind farm projects are being built or planned than ever before.

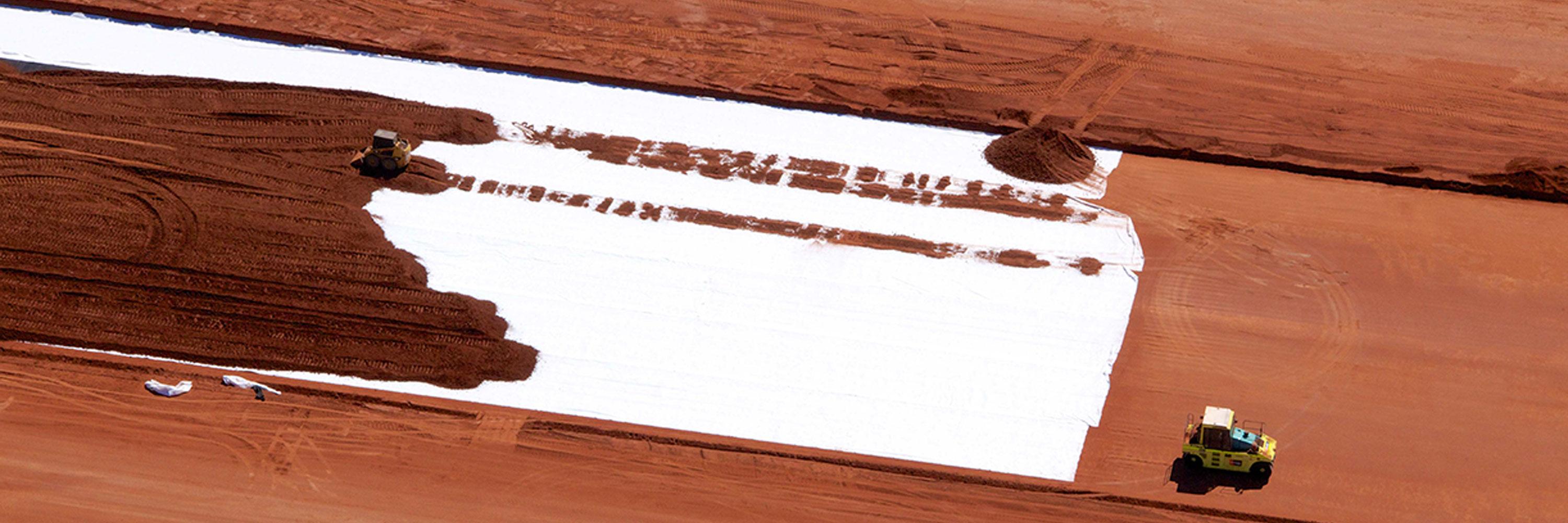

Due to the size and nature of the turbines, wind farms are usually positioned in low population areas which have low bearing capacity or are otherwise unsuitable for more traditional development. Therefore, due to the low bearing capacity of such areas, and the considerable weight of the construction equipment and turbine components, the construction of strong access roads is critical.

Typically the base course under these roadways is made of crushed gravel that must provide efficient load distribution of the stresses transferred from traffic. In all cases it is important that the shear strength of the subsoil, which in general can be very low, is exceeded by the base course material. A cost effective method to achieve a long term solution for low strength subsoils is to use a geogrid such as Combigrid® between the subsoil and the overlaying base course.

What is Combigrid®?

Combigrid is a geogrid that combines the rigidity and reinforcement characteristics of a traditional extruded polypropylene or polyester grid with the structural stability of a woven fabric. Combigrid® geogrids are mainly used in conjunction with soft and low CBR soils, where a mixture of reinforcement, separation and filtration is needed.

What are the advantages of Combigrid® over woven products?

There are a number of reasons that geocomposite geogrids such as this outperform simple woven geotextiles in high stress applications like wind farm access roads.

A geogrid’s quality can be defined in many ways (long-term design strength, cost, etc.), but success begins with the individual bars. It is in these bars that performance rests: strength transfer, elongation, installation and degradation resistance and sustainability. The tensile performance and dependability of Combigrid® reinforcement is rooted in its flat, extruded geogrid bars and how they mobilize high strength at low strain.

More Strength = Less vertical deformation

It is necessary to align the stress/strain behaviour of the installed geogrid to the elongation behaviour of the soil. The performance of the geogrid at a stress/strain ratio in the range of 2% is therefore important, and it is here that Combigrid® shows its strength.

The tensile strength of Secugrid® (Combigrid®’s reinforcement component) is excellent at low elongation. The Secugrid® bars excel at these realistic design levels and show an optimum strength transfer in a design range of less than 2%, demonstrating a high modulus. As the geogrid is much stiffer in tension than the base aggregate, lateral stresses and strains in the reinforced base aggregate are reduced and significantly less vertical deformation can be expected.

Reduced shear stress

The manufacturing process of a geogrid is useful to know too. Monolithic, extruded bars like that of Secugrid provide greater torsional rigidity than a flexible woven geogrid. Combigrid®’s flat, welded geogrid junctions perform very well in torsional rigidity tests.

When traffic passes over a geogrid-reinforced granular base course, a shear stress develops in the aggregate on the plane of the grid. This shear stress changes in magnitude and direction as the wheel passes. The changing direction causes a twisting motion in the geogrid. The main motion of the aggregate is outward from the wheel, but the stress on an individual particle during this migration changes from forward to outward, to backward. Geogrids with high torsional rigidity provide greater resistance against torsional stresses, and this means that they provide more effective interlock with and lateral restraint of the base course material.

In roadway design, the torsional rigidity of a geogrid is an important factor in determining the traffic benefit ratio (TBR), which is the potential service life extension of a reinforced vs. an un-reinforced design.

The solution on soft soils

Reinforcement alone is not always enough. Additional engineering functions may be required in the reinforcement layer, such as separation, filtration and drainage. Combigrid® combines all of these requirements in a single product. This composite product combines a Secugrid® geogrid with a needle-punched Secutex® nonwoven geotextile.

The geotextile is firmly welded between the reinforcement bars, providing exceptional support for soil stabilisation, separation and filtration applications, in addition to the geogrid’s reinforcement strength.

For more information please contact amir@globalsynthetics.com.au