Naue Secugrid® Geogrid

Secugrid® geogrids are polymeric products formed by joining intersecting ribs. They have large open spaces, also known as “apertures.” The directions of the ribs are referred to as the machine direction (md), oriented in the direction of the manufacturing process, or the cross-machine direction (cmd), perpendicular to the machine direction ribs. Geogrids are mainly made from polymeric materials, including polypropylene (PP), high-density polyethylene (HDPE), and polyester (PET).

Product Information: In the application of base reinforcement, there is a design intention to improve the bearing capacity of an existing subgrade while minimising the use of granular materials in base course or pavement designs. Secugrid® geogrids offer an excellent solution for renewable projects seeking sustainable alternatives.

For renewable-focused applications, the preferred geogrid is a biaxial “stiff” high modulus product. Secugrid® is a low-strain biaxial geogrid with equal strength in both directions and outperforms many other geogrids with its exceptional strengths at strain levels of 1%, 2%, and 5%. By utilising stiffer geogrids like Secugrid®, renewable projects can efficiently handle loads and operate at strain levels appropriate for optimal pavement performance.

Applications: Secugrid® geogrids find extensive use in various markets, including base reinforcement, earth retaining wall construction (including veneer stabilisation), the segmental retaining wall market, embankment reinforcement, and pile cap platforms. Biaxial geogrids, primarily employed in base reinforcement applications, play a pivotal role in renewable projects.

Renewable applications of geogrids involve enhancing the performance and lifespan of renewable infrastructure. Engineers utilise geogrids such as Secugrid® to improve gravel bases over poor soils, reduce the required amount of gravel in base course designs, and extend the life of surface coverings, be it concrete, asphalt, or other renewable materials. Secugrid® geogrids are effectively deployed beneath parking lots, airport runways, gravel construction roads, highways, dam levees, and railroad tracks, providing increased stability, load-bearing capacity, and long-term sustainability.

Features and Benefits: Secugrid® geogrids are meticulously manufactured using high-quality polypropylene (PP) or polyester (PET) bars firmly welded together, ensuring a structurally sound and stable geogrid system. These geogrids feature highly orientated bars that are uniformly extruded and pre-stressed, resulting in high tensile strength even at low strains. The roughened surface of the individual bars enhances frictional properties, enabling effective load transfer from fine-grained materials to the Secugrid® reinforcement.

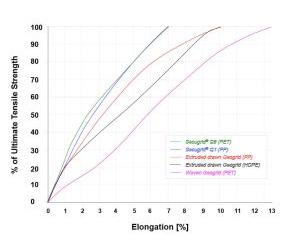

One of the key advantages of Secugrid® is its exceptional stress-strain behaviour at low elongation. This unique characteristic significantly reduces road deformation, leading to improved long-term performance (see graph below).

Image: Typical stress-strain curves for Secugrid® and market available geogrids

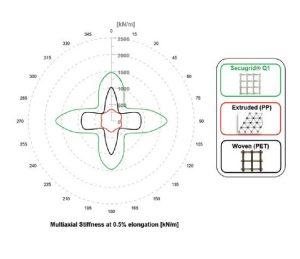

As loads are applied to the road surface, the aggregate interlocks with the Secugrid® geogrid layer. The superior stiffness of Secugrid® ensures excellent aperture stability, providing high lateral restraint for the aggregate layer. Furthermore, the high torsional stiffness of Secugrid® offers resistance against twisting motions, effectively confining the interlocked aggregate layer both laterally and vertically. With its radial tensile strength at low elongations, Secugrid® prevents subgrade deformations and preserves the reinforced roadway’s surface, ultimately increasing the road’s bearing capacity.

Independent testing has shown the beneficial impact of Secugrid‘s high radial stiffness when compared to similar available products in base course structures – see below.

Image: Radial secant stiffness of Secugrid® and other geogrids at 0.5% elongation

At Global Synthetics, we are dedicated to offering geogrid solutions that cater to the renewable sector, facilitating greener and more sustainable civil engineering practices. By incorporating Secugrid® geogrids into renewable infrastructure projects, engineers can achieve superior performance, minimise environmental impact, and actively contribute to a more sustainable future.

To learn more about how this product can contribute to renewable projects, please visit our blog focusing on sustainable solutions for projects like wind farms.

Naue Secucalc Software: To assist you in your design, this software has been designed to allow a generic calculation of aggregate base material in unreinforced and Secugrid®, reinforced applications, such as under roadways, access/haul roads, parking lots or similar applications. Secugrid® geogrid reinforcement extends project service life, improves performance, reduces excavation, and lowers overall costs. SecuCalc 2.2 is based on test trials and 30+ years of engineering knowledge.

Secugrid® is a registered trademark of Naue GmbH & Co. KG in various countries.