Naue Combigrid® Composite Geogrid

Geogrids are polymeric products formed by joining intersecting ribs. They have large open spaces, also known as “apertures.” The directions of the ribs are referred to as the machine direction (md), oriented in the direction of the manufacturing process, or the cross-machine direction (cmd), perpendicular to the machine direction ribs. Geogrids are mainly made from polymeric materials, including polypropylene (PP), high-density polyethylene (HDPE), and polyester (PET).

Product Information: Combigrid® is a flat composite geogrid from the Secugrid® product range. Incorporated into the geogrid construction is a nonwoven geotextile component for specific applications where reinforcement of problematic soils is required, combined with the additional functions of separation and filtration. This combination provides reinforcement, stabilisation, filtration, separation, and drainage in a single product.

The unique manufacturing process produces structured, high-strength, monolithic, pre-stressed polypropylene, or polyester bars with a continuous molecular structure. The extraordinarily high extensional stiffness of Combigrid® efficiently reduces deformations in the subgrade, which extends the service life of modern infrastructure.

Applications: Geogrids play a crucial role in renewable energy projects, offering environmental protection, cost efficiency, and operational advantages for sustainable development worldwide. The global investment in renewable energy has seen significant growth, with wind energy emerging as the fastest-growing sector. Geosynthetics, including geogrid reinforcement, have played a vital role in enabling the construction of these projects, particularly wind farms.

Accessing renewable wind energy often presents engineering challenges due to complex terrain and soil characteristics. Wind farms require expansive areas with stable soil conditions for construction, including access roads and turbine pads. Geogrid reinforcement, such as Combigrid®, proves indispensable in providing soil stability and facilitating access to wind farm sites.

The utilisation of geosynthetics, specifically geogrid reinforcement, has contributed to the success and sustainable development of renewable energy projects worldwide. By incorporating high-performance geogrids like Secugrid® and Combigrid® into these projects, engineers can overcome access challenges, enhance soil stability, and promote the efficient utilisation of renewable energy resources.

Features and Benefits: Combigrid® stands out by combining reinforcement with additional engineering functions required in the reinforcement layer, including separation, filtration, and drainage. This composite product integrates a Secugrid® geogrid with a needle punched Secutex® nonwoven geotextile. The geotextile is firmly welded between the reinforcement bars, offering exceptional support for soil stabilisation, separation, and filtration. Moreover, Combigrid® exhibits an interlocking behaviour equivalent to that of Secugrid® due to its unique manufacturing process.

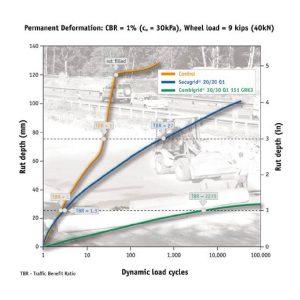

Combigrid® offers distinctive features such as excellent separation, filtration, and drainage characteristics, making it particularly suitable for subsoils with a CBR value of less than 3%. It provides remarkable performance in reinforcing base courses, working platforms, temporary access roads, paved roads, and pipeline trenches. Large-scale laboratory tests have demonstrated its exceptional durability, preventing deep traffic ruts even after a significant number of load cycles.

Image: Combigrid® and Secugrid® traffic benefit ratio over a very weak subsoil, compared to an unreinforced design in a large-scale lab test.

By incorporating Combigrid® into infrastructure projects, engineers can benefit from its superior reinforcement properties, enhanced soil stability, and multifunctionality. It enables efficient utilisation of renewable energy resources while contributing to sustainable development and long-lasting infrastructure.

Combigrid® is a registered trademark of Naue GmbH & Co. KG in various countries.