Do you have this product in NZ?

Yes: We have an office in NZ. Contact details: Phone: 0800 510 120 Address: Auckland – Christchurch Sales Manager: Laurie Vercoe Email: laurie.vercoe@globalsynthetics.co.nz

What is the max slope we use these protection mats?

The soil conditions on a particular site determine the maximum slope for both ARMORMAX 75 and PYRAMAT 75. It is possible to stabilize nearly vertical slope faces with these products. For specific projects, please involve a Global Synthetics or Propex Engineer to assist in the appropriate application of these systems.

Is it possible to use in a bushfire prone area?

It is possible to use ARMORMAX 75 and PYRAMAT 75 in brushfire prone areas. The United States Forestry Service published research in the Soil Science Society of America Journal defining the effects of wildfire on soil heating in both disturbed and undisturbed soils. Research shows the maximum temperature of dry soil (<20% volumetric moisture) at 5cm is approximately 180° Celsius and at a depth of 10 cm it is well under 100° Celsius. With ARMORMAX 75 and PYRAMAT 75 having a melt-point of a 160° Celsius, a minimum soil cover of 7 to 8 cm allows its use in brushfire prone areas.

Another question about the earth anchor – do they ever get tested for pull-out resistance following construction to confirm design assumptions?

The Engineered Earth Anchor (EEA) in the ARMORMAX System is sometimes tested for pullout resistance following installation. There are two different reasons for testing. First, with the smaller Type B1 anchors used for tie down only, the Engineer may dictate, through the project specification, randomly load testing a small percentage of anchors as a quality control measure confirming the Contractors installation method. Secondly, the Engineer mandates in field load testing on the larger, Type B2 and B3 anchors, when there is low confidence in the soil parameters used in the initial surficial slope stability design.

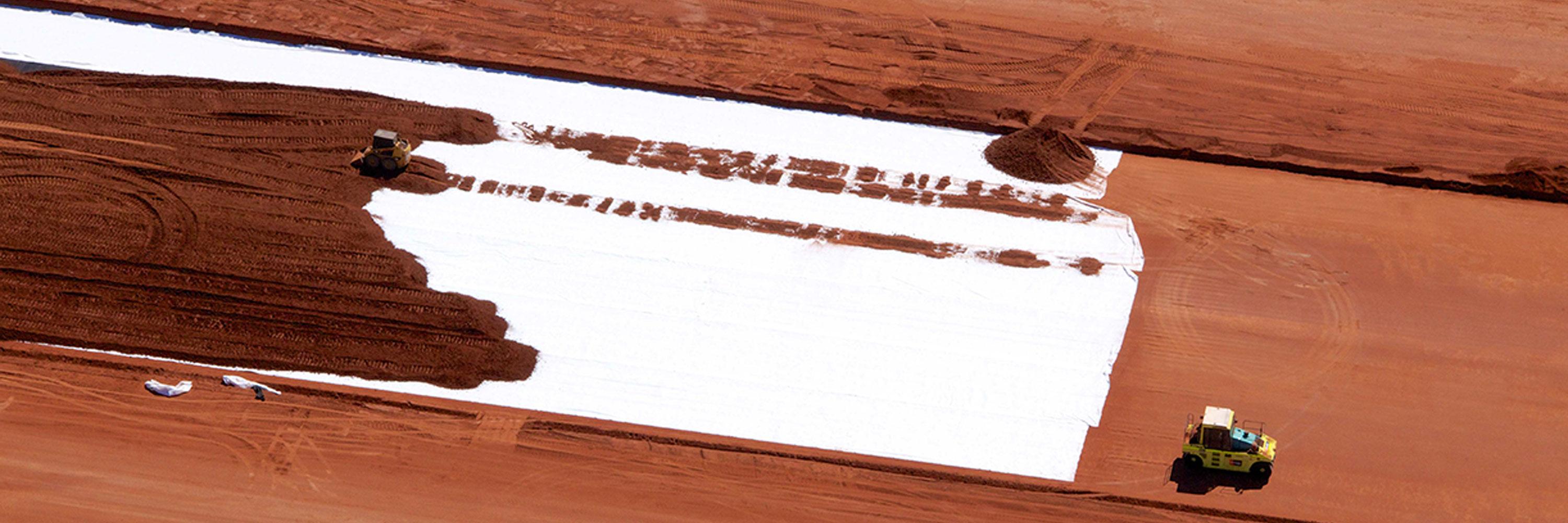

Are non-permeable materials available for application in something similar to an over flow earth bund, which is not allowed to infiltrate but may be affected by erosion from torrential rain?

Non-permeable materials are available for such applications. Please contact Global Synthetics for more information and details.

Are you able to send me a copy of this recording so i can share with the team as well?

A link for the video of this presentation will be provided, stay tuned.

Will the impact jack hammer drive the anchors into Mudstone?

Standard ARMORMAX 75 requires the majority of anchors be driven to design depth and frequency. Occasionally, ARMORMAX 75 uses a rock bolting systems to attach to a hard underlying surface un-penetrable by the standard anchor. In the case of mudstone or other sedimentary rocks, drive test anchors to determine the viability of this system prior to design.

How do you define surficial failure? What is the suggested failure depth?

ARMORMAX 75 stabilizes surficial slope failures occurring on globally stable slopes. The target failure occurs within the first 1 to 2 meters of the slope face and can be a result of slope geometry, heavy rainfall, change in surcharge loading at the top of slope, or ground water. A block of soil moving down the slope is a common identifier of a surficial slope failure.

Do you have a programme/calculations available to check MSE walls for Pyrawall?

Propex offers ECDESIGN for the design of ARMORAX 75 and PYRAMAT 75 in hydraulic applications. For PYRAWALL, use Propex’s GEODESIGN. It is a free online application checking sliding, overturning, bearing capacity, and internal reinforcement strength.

Please contact Global Synthetics at amir@globalsynthetics.com.au for free design assistance and technical support.

With Environmental certifications (ie FSC) can we get native grasses and plants?

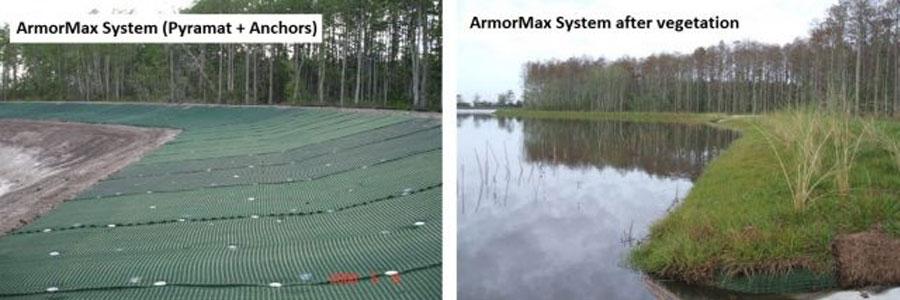

The benefit of ARMORMAX 75 and PYRAMAT 75 is that it gives the designer more opportunity to use natural solutions instead of ones traditionally based on rock or concrete. Simply, if the selected vegetation will grow at the project site, the ARMORMAX 75 and PYRAMAT 75 will only increase its chance of survival and propagation.

Various projects with native vegetation have been completed in Australia so far: