In order to avoid water condensation in the GCL, can we open holes in the upslope for the gases to escape?

This is not effective nor practical. The evaporated moisture is encapsulated under the geomembrane wrinkle. Wrinkles are connected to each other and don’t have a regular pattern and may not necessarily go all the way to the top of the slope.

This was a question raised early within the webinar. It was answered later in the presentation: For exposed side slopes, best practice is to utilise a coated GCL as it prevents the condensation mechanism.

Can baffles be incorporated into the composite to control the migration?

Same as above.

Can you comment on whether downslope erosion is also likely to be a problem for composite liners comprising GMB and compacted clay?

A compacted clay liner is not recommended as it is vulnerable to desiccation. This is a far greater risk to the composite liner performance. Desiccation, even if it is only small cracks, can increase the interface transmissivity by many orders of magnitude and this destroys the composite liner action. Kerry says that; If one’s going to use compacted clay you should use a GCL on top of it.

Some research suggesting the polymer does all the good before it leaves the GCL; to what extent would you agree with this?

It depends on what one wants to achieve. If the goal is to achieve a higher swell (specially for the lower quality bentonites) or cation exchange in the beginning, polymer modification will help. But GCL that utilise a polymer modified bentonite are susceptible to elution, therefore the polymer will not stay in the GCL for a long time to provide these benefits constantly. Queens University large scale field trials demonstrated that polymer elution occurred, and down slope bentonite erosion occurred after 15 months. If the polymer is eluted, any benefit they provided are no longer present.

On the other hand, some other performance parameters such as downslope erosion resistance, fluid loss, index flux, and permeability are required for a long term or even the whole design life of the project and cannot be relied on a temporary component that elutes from GCL.

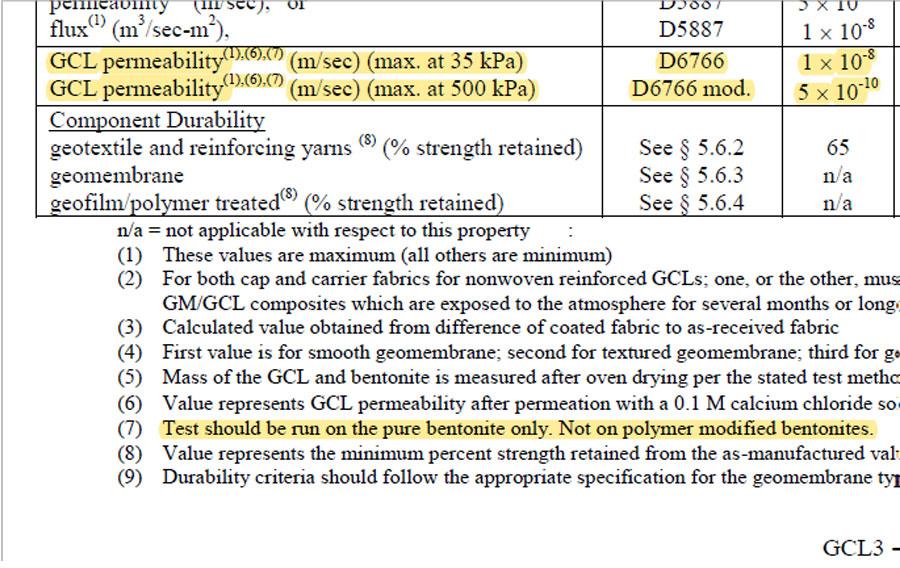

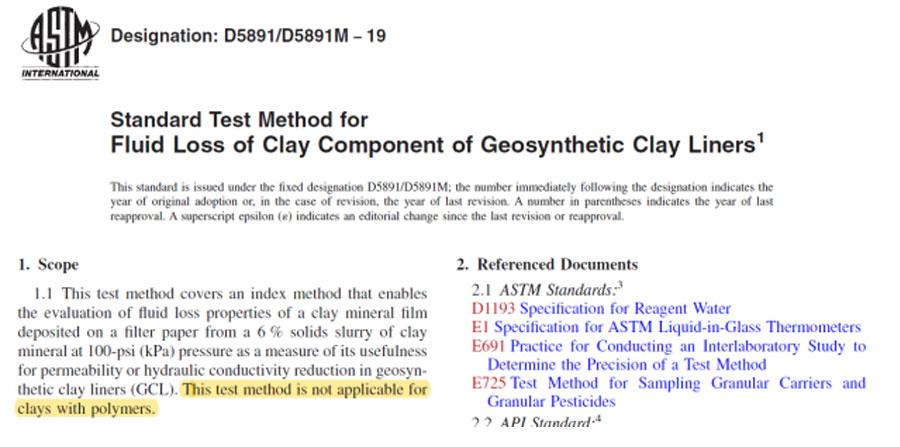

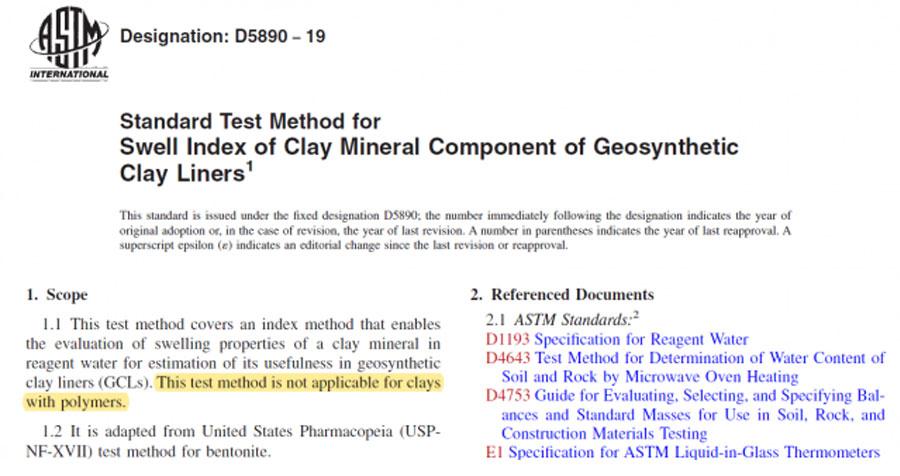

That is why GRI_GCL3 guidelines and ASTM Test methods for GCL and bentonite performance all state that these properties should be tested using the base pure bentonite, not with polymer modified bentonite. GRI_GCL3 and ASTM D5890 and ASTMD5891 extract included below:

Any suggestions for design of composite liners on slopes if you use a coated GCL under a geomembrane. How you can create less friction above the geomembrane than below it, so that the liner is not stressed during waste settlement and consolidation, and still maintain global stability of the waste?

Typically, to control the downslope erosion and potential for desiccation of the GCL on exposed side slopes, use a 200sgm (0.2mm thickness) smooth coated GCL facing up.

How can we get access to the paper written by Di Battista, et al?

Copy attached.

DiBattista, V., Rowe. R.K., Patch, D. and Weber, K. (2020) PFOA and PFOS Diffusion through Geomembranes at Multiple Temperatures, Waste Management, 117: 93-103.

Click Here For Di Battista Paper

Some landfill owners are aware of the downslope erosion issue, but believe it may not be a high risk as the slope liner is not as acritical as base liner. What is your opinion about that?

Kerry’s response received a good response from many participants on the day: As a designer, if you believe that to be the case then don’t use a composite liner, however if you do, then make sure the composite liner you specify works !. For exposed side slopes, GCL downslope erosion and desiccation need to be controlled, and best practice is to utilise a coated GCL as it prevents the downslope erosion mechanism and desiccation. If you can cover the slope with 300mm gravel, then that is even better.

How much waste covering I assume need to be applied over the composite to protect them from exposed erosion?

Manufacturers recommendations of 300mm soil cover as a minimum or equivalent pressure.

Was there a specific wrinkle height that was observed to trigger or the bentonite erosion process (i.e. to no recovery)?

Bentonite erosion occurred at all wrinkle locations and all weld locations between panels.

If you have further queries please email The Tech Team at: gbs@globalsynthetics.com.au