Case Study: Tasmania hits goal of 100% renewable energy Granville Harbour Windfarm Access Roads and Hardstands

Date: Sept 2019 - 2020

Location: Granville Harbour, Tasmania

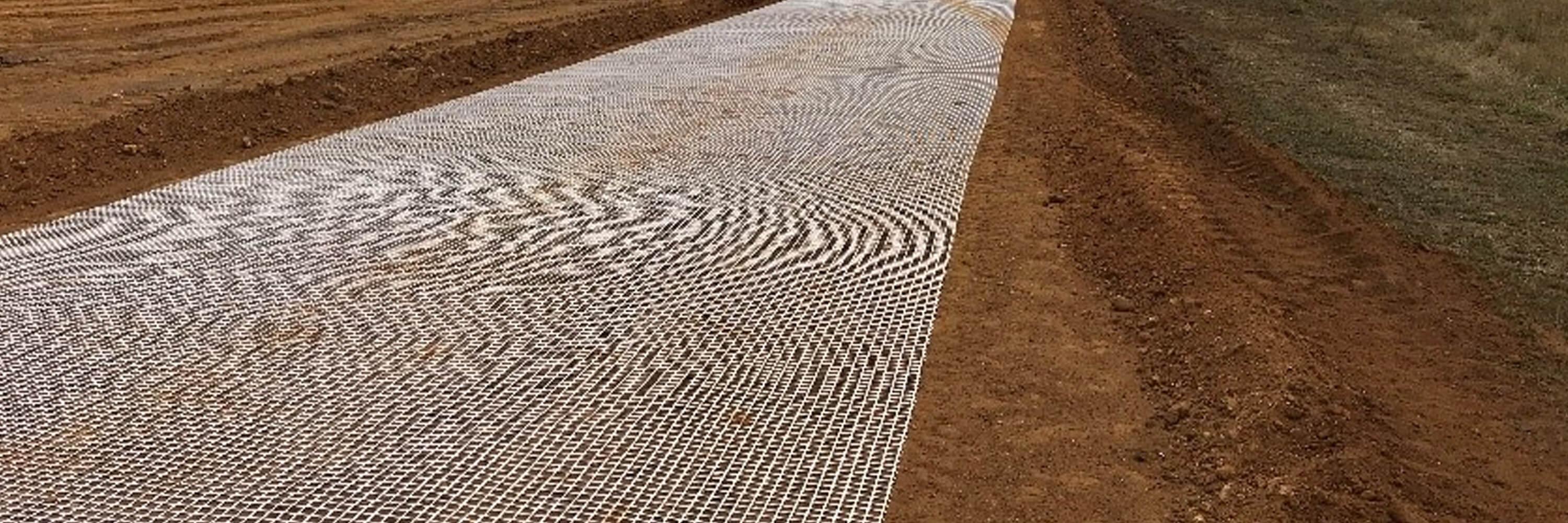

Product: 70,000sqm Secugrid® Geogrid

Project Background:

Granville Harbour windfarm is located on Granville Farm on the West Coast of Tasmania.

The Granville Harbour Wind Farm site is approximately 840ha in size and is located on an elevated basalt cap of improved graving pasture, 1.5km inland from the coast and will consist of 31 wind turbine generators.L

ucas TCS and RJE Global formed a joint venture (branded LRC Consortium) to conduct the project and were responsible for the design and construction of all associated civil and electoral infrastructure required. The scope of work consisted of:

31 Wind Turbine Foundations.

20 km of access track road construction for the 31 wind turbines.

Problem

Located north west of Zeehan, the area is predominantly farmland sustaining up to 1850 head of premium beef cattle. The site surface comprises variable ground surface conditions with undulating paddocks of pasture, swamp and woodland, underlaid with Brown, medium to high plasticity sandy to clayey silt. Based on the grading results and Atterberg limits, the subgrade material at the site was generally described as a medium to high liquid limit (sandy) silt with low to moderate reactivity.

In addition, the unfavourable ground conditions and heavy rainfall made the project unique, and innovative thinking was required for construction of access roads and hard stands.

The site conditions have made the project an environmentally delicate construction zone with disruption of the surrounding area to be kept to a minimum.

Solution

Access to the area was very limited and access roads needed to be constructed to facilitate the transportation and installation of the turbines. The access roads and hardstands needed to be reinforced to accommodate this heavy vehicle access and heavy loads from the cranes. Geosynthetics were utilised to reinforce the soil and provide a sustainable solution and reduce the thickness of the roads and hardstands.

Due to the massive weight of the turbine components and cranes, soil reinforcement and stabilisation was a crucial factor. Secugrid® laid and welded biaxial geogrid was used as the high modulus high performance geogrid to reinforce the soil.

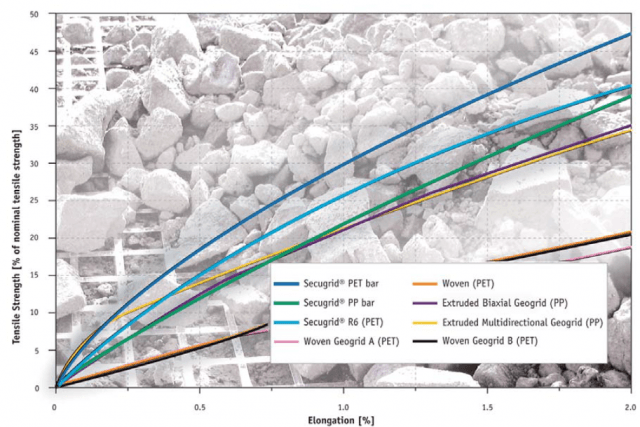

Secugrid® is a German made laid and welded biaxial geogrid, made of pre-stressed high modulus bars with textured surface. This technology has made Secugrid® a geogrid with the highest stiffness at low elongations compared to other available geogrids. With this benefit, Secugrid® can provide a high level of reinforcement and stabilisation even at very low elongations.

Secugrid® has been used successfully for a long time in many roads and rail projects. The high performance of Secugrid® has been verifies through various independent full-scale tests and trials including the full-scale trials by US DOT and Montana State University (FHWA/MT-14-002/7712-251), Technical University of Clausthal (Germany), and various other studies worldwide including Australia.

Results

Using Secugrid® could provide a sustainable solution for construction on soft and reactive soils in Granville Harbour windfarm. This solution reduced the required thickness of the granular layer for access roads and hard stands, hence providing a considerable saving in the costs and construction time.

Benefits of Secugrid® use in windfarms:

high strength at low strains

embossed bars provide frictional performance improving surface

extraordinary torsional

reduction in aggregate required for construction reducing the carbon footprint aswell