Introduction

The Engineering solutions for natural disasters include:

Sustainable engineering solutions for quick and economical yet technical and durable rehabilitation and repair of the damages and failures from natural disaster

Resilient infrastructures that can withstand and manage/prevent natural disasters such as flood and bush fire

This blog series will cover both above categories including:

Part 1 (To Repair damages from NATURAL disasters):

Shallow plane slope failure repair

Major slope failure repair

Pavement failure repair

Part 2 (To prevent and/or reduce damages from NATURAL disasters):

Flood-Resilient Infrastructure, including resilience flood protection levees, and resilience stormwater channels.

Bush fire resistance permanent erosion control techniques.

Part 1 – To Repair damages from disasters:

Slope failure

Time and costs associated with the maintenance, repair, and reconstruction of failing slopes are financial burdens. Conventionally acceptable methods of slope repair such as substantial excavation and replacement often experience degradation and undesirable environmental impacts. Alternative sustainable methods for stabilisation of failing slopes are thus often highly demanded.

A. Shallow plane slope failure

Alternative sustainable solutions for repairing shallow failures include passive in situ remediation techniques that incorporate vegetation as a component of the stabilisation strategy. These systems provide both, slope stability and erosion control at the same time. It should be noted that although erosion is technically not a mode of slope failure, it can often be considered as a root cause and can end up with similar undesirable consequences.

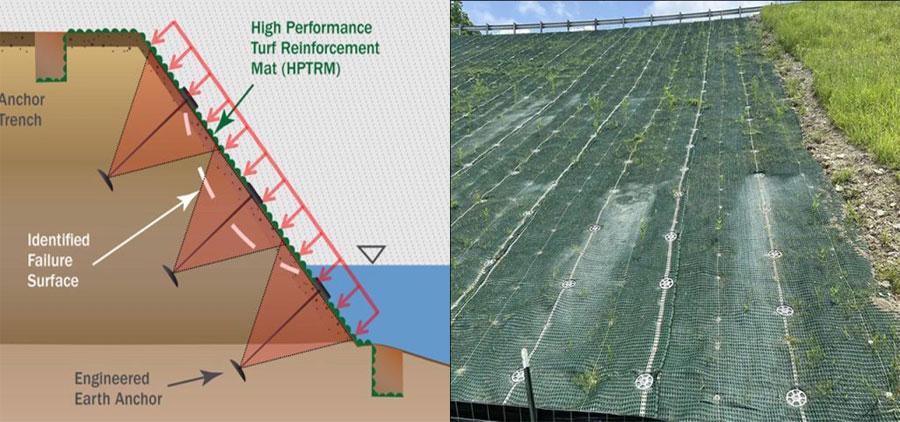

Armormax® Engineered Earth Armoring System (EEAS) is such a method. It is a multi-component system that includes Pyramat®75 High Performance Turf Reinforcement Mat (HPTRM) installed on the slope surface, permanently secured using Engineered Earth Anchors in a designed pattern, driven to a designated distance below the surface of the slope.

Photo: Armormax system (Courtesy: Solmax)

Each component of the Armormax® has a unique purpose enabling the whole system to serve as an effective solution to provide slope stability against both translational and rotational sliding failures. The Engineered Earth Anchors provide resistance to driving forces, incorporating Pyramat®75 HPTRM with a high tensile strength (typically more than 40kN/m in both directions) for distributing load amongst the anchors and providing further resistance to movements. Pyramat® 75 HPTRM also provides a permanent layer for the establishment and reinforcement of vegetation through the three-dimensional matrix of the HPTRM, which will control surface erosion and assist in resisting surface shear forces.

Photo: Slope failure repaired using Armormax® system” (Courtesy: Solmax)

How does Armormax® system work?

Gain a deeper understanding of the Armormax® system’s inner workings. Explore our detailed article on its design and performance modeling.

Design life?

The Pyramat® HPTRM component of the Armormax® is highly UV stabilised. This system can be used either with or without vegetation for long term designs up to 100 years. Of course, facilitating the establishment of vegetation within the system where possible provides additional elements of strength to alleviate soil mass mobilisation over time. The Pyramat® 75 HPTRM provides reinforcement to the vegetation.

Photo: Armormax® system with no vegetation, Gladstone, QLD, Australia

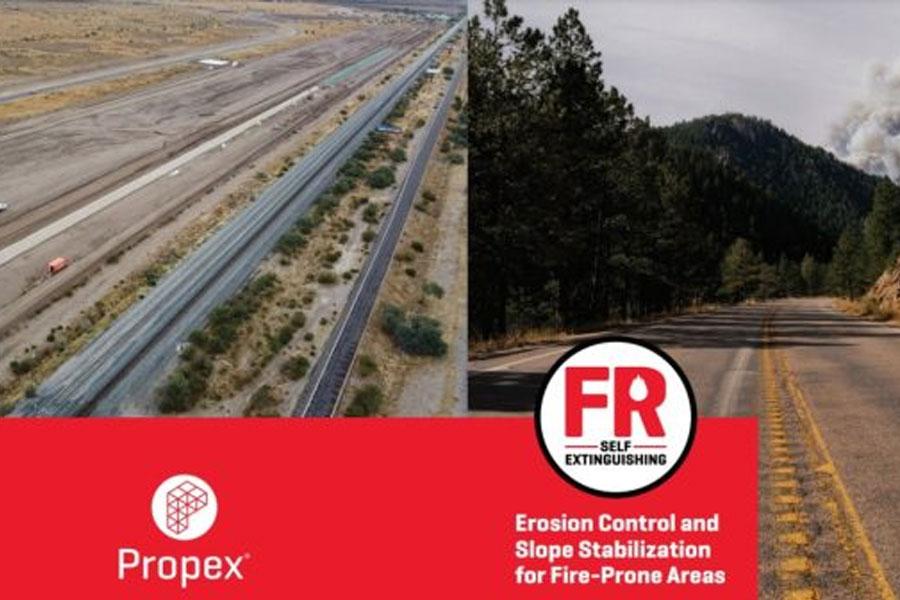

What about bushfires?

Propex Pyramat® TRMs are now engineered to mitigate fire risk and increase the resilience of wildfire prone areas using non-halogen fire retardant technology.

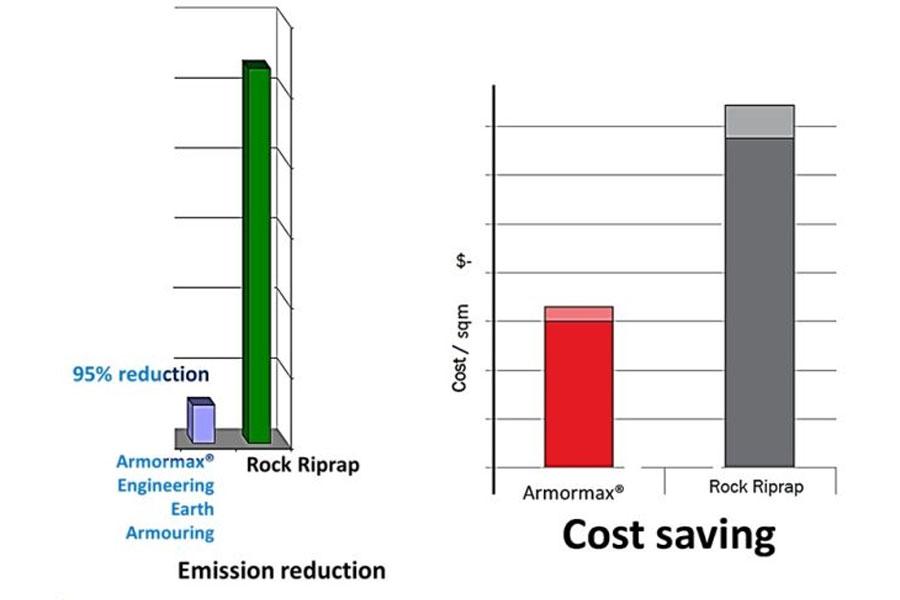

Sustainability check

Pyramat® is the only HPTRM to have a verified carbon footprint by an independent third-party. From cradle-to-grave, the carbon footprint of 1m2 of PYRAMAT® 75 HPTRM is 2.7 kgCO2e, which is up to 30 times lower that concrete and rock alternatives.

Photo: Armormax® sustainability real project calculation as an example

Armormax provides a sustainable and resilience solution for shallow slope failure repairs against natural disasters.

Photo: Armormax® system, Brisbane Valley Remediation, QLD TMR

Dive deeper into the technical information and aspects of Armormax for shallow slope stability. Explore the comprehensive technical paper presented at ANZ2023.

Watch the recording of our FREE webinar on Surficial Slope Stability with Engineered Earth Armouring System. Simply register/login in to the Global Synthetics Hub and access the recordings below.

Part 1 (October 28, 2020): SURFICIAL SLOPE STABILITY WITH ENGINEERED EARTH ARMORING SYSTEM – PART 1

Part 2 (December 2, 2020): SURFICIAL SLOPE STABILITY WITH ENGINEERED EARTH ARMORING SYSTEM – PART 2

Need assistance with design or a technical proposal? Contact us at info@globalsynthetics.com.au

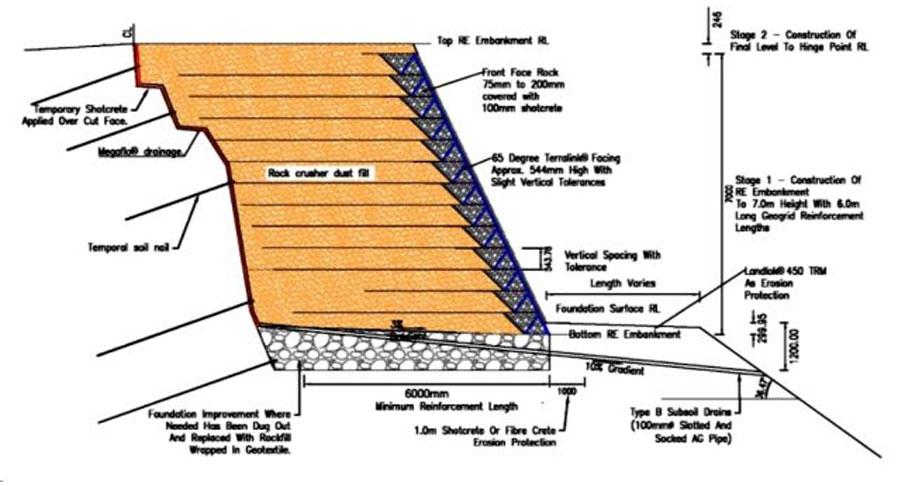

B. Major slope failure repair – Geogrid reinforced slopes

Slope failure is one of the major damages from natural disasters such as flood and earthquake. The sustainable solution to repair such failures involves the use of geogrid reinforcement, as they can lead to using less material because the very steep slope can be maintained and the vegetative cover is possible if needed. The construction of such systems are very quick.

Photo: Railway Slope failure repair with Secugrid® reinforced slope (Courtesy: NAUE)

Photo: Mt Morgan Slope failure repair with AceGrid® reinforced slope, QLD

Photo: Mt Morgan Slope failure repair with AceGrid® reinforced slope, QLD

A detailed analysis of the Mt Morgan failure repair project.

Here’s a comprehensive overview of our geogrid product range and its applications.

For FREE design assistance and technical proposal, please contact us: info@globalsynthetics.com.au

C. Major slope failure repair – Green slope/MSE Wall (Pyrawall®

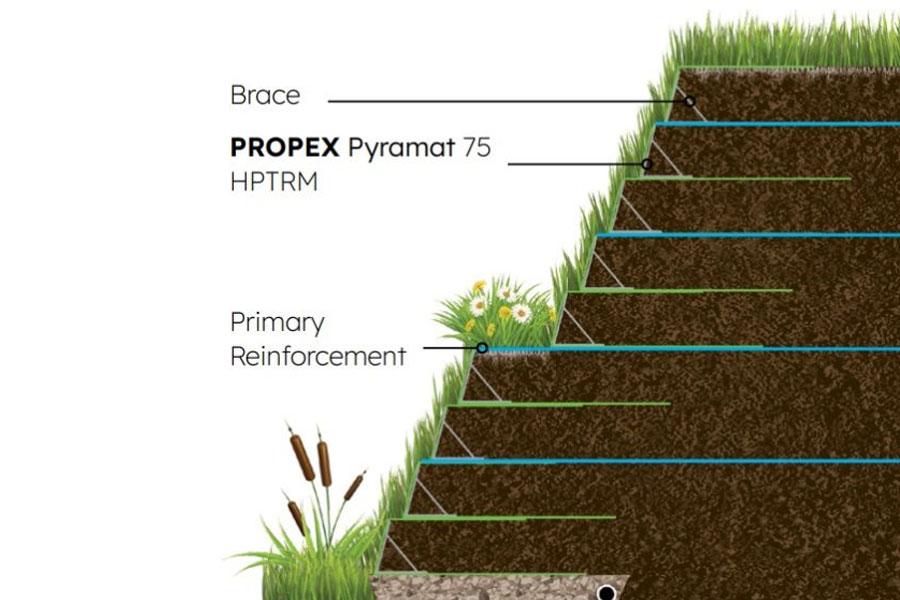

PYRAWALL® is an engineered wrap-face vegetated solution for constructing reinforced-soil walls and steepened slopes. The system consists of PYRAMAT® 75 High Performance Turf Reinforcement Mat (HPTRM) and fiber-composite internal bracing. Featuring flexible setback and alignment, PYRAWALL is customizable to unique site conditions and geometrics.

Pyrawall® Produces reinforced soil mass to resist lateral earth pressures and provides immediate erosion protection upon installation. Is a vegetated Best Management Practice Solution with superior UV resistance for up to 100 years of design life. It eliminates the need for temporary metal bracing or removable forms to improve installation efficiency, provides durable, permeable, and vegetated wall face for long-term performance and aesthetics, and make it possible for on-site soil to be used for infill eliminating the cost and carbon footprint of importing soil.

Photo: Pyrawall, St. Mounds View, Minnesota, USA (Courtesy: Solmax)

Photo: Pyrawall® repair solution, Lavers Hill, VIC, Australia

Please refer to the dedicated webpage for detailed information on the Pyrawall® Engineered Wrap-Faced Vegetated Solution.

For FREE design assistance and technical proposal, please contact us: info@globalsynthetics.com.au

Watch the recording of our FREE webinar on Resilient flood protection systems and rehabilitation solutions. Simply register/login in to the Global Synthetics Hub and access the recording.