It has been established over recent years that geosynthetics are fundamental to ensuring sustainable developments. The use of geosynthetics in engineered systems serves to protect the environment, conserve water, controls surface erosion, and increases the longevity of critical infrastructure

Sophisticated lining geosynthetics typically used in mining applications not only suppress gases being emitted but reduce construction costs, building time, as well as the need for heavy vehicles. Consequently the amount of pollution emitted is considerably decreased.

The application of geogrids for base soil reinforcement in traffic areas has not only resulted in durable, safe and cost-effective solutions for roads and pavements but also lead to solutions that minimise the negative impact of construction on the environment.

Erosion control solutions are by far offering the greatest environmental benefits and maintaining a minimal carbon footprint, by promoting growth of vegetation and improving water quality. The traditional way to control erosion in highly erosive areas was using hard-armour erosion control techniques such as concrete blocks, rock riprap and reinforced paving systems. Although these permanent methods can withstand great hydraulic forces, they are costly and they do not provide the pollutant removal capabilities of vegetative systems. These systems need special equipment to install and can present a hazard to people and the environment. Filters also need to be designed properly and planting between stones can be difficult (EPA, 1999; Rivas, 2006; GMA, 2009; Alberta, 2011). Before the invention of Turf Reinforcement Mats (TRMs), rip-rap and concrete were traditional “hard armour” solutions when vegetation alone could not provide the required permanent erosion protection for high velocities and shear stresses.

Our Turf Reinforcement Mats (TRMs) erosion control products, sourced from renowned international manufacturer Propex, offer more than just a natural visual appearance. Propex TRM products, combined with sustainable design, are excellent permanent erosion control alternatives to hard armour approaches. Propex TRMs can replace rock riprap, concrete channels, rock mattress or interlocking concrete block systems, resulting in an overall cost reduction. The hydraulic performance and design values of Propex TRMs are verified through independent full scale flume testing at Colorado State University.

Traditional concrete drains and rock beaching can be expensive and difficult to construct, not to mention the potential problems they may cause to the surrounding ecology.

Traditional concrete drains and rock beaching can be expensive and difficult to construct, not to mention the potential problems they may cause to the surrounding ecology.

TRMs present a suitable alternative to these hard armour techniques, and have proven ability to substantially increase the erosion resistance of vegetation, allowing for use in high velocity/shear stress areas.

TRMs are typically used in high flow ditches and channels, steep slopes, stream banks, and shorelines, where erosive forces may exceed the limits of natural, unreinforced vegetation or in areas where limited vegetation establishment is anticipated. TRMs with higher shear resistance are called High-Performance TRMs (HPTRMs) and are being used for more critical conditions.

The TRM protects soil and promotes vegetation growth while removing potential pollutants through soil sedimentation and infiltration. TRMS have also been proven to support a living shoreline, as opposed to hard armouring, which can decrease creekside vegetation and therefore adversely impact marine life populations.

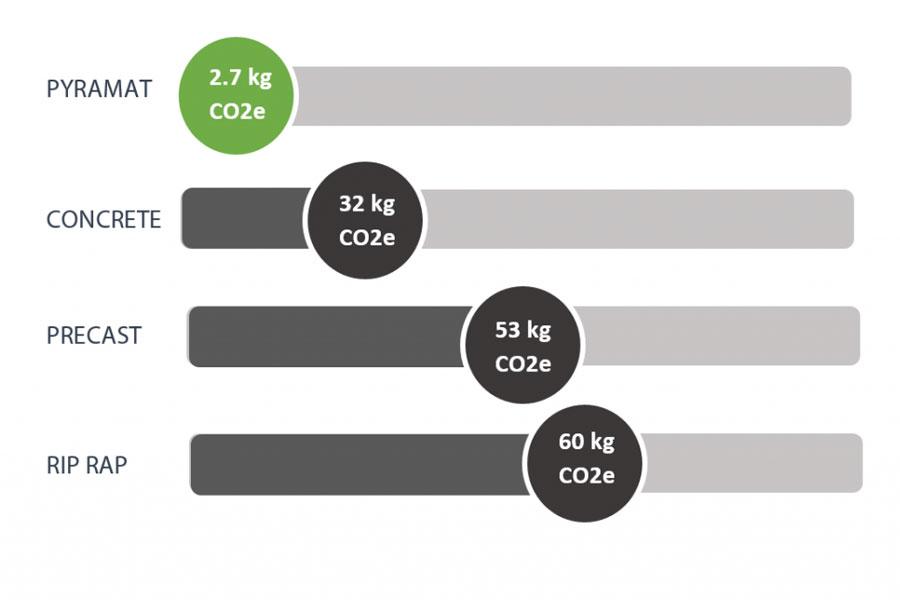

Propex recently became the first High-Performance Turf Reinforcement Mat (HPTRM) manufacturer to verify the carbon footprint of its erosion control solutions. The cradle-to-grave carbon footprint of PYRAMAT® 75 HPTRM is 2.7 kg CO2e per 1m2 of material, which is equivalent to driving about eleven km.

PYRAMAT®’s lifecycle was factored into its cradle-to-grave carbon footprint calculation. Conducted by SCS Global Services, an international leader in third party certification and environmental standard development, the result was then additionally verified through additional independent third party review conducted by Dr Tom Gloria of Industry Ecology Consultants. The studies found that PYRAMAT® meets the greenhouse gas protocols and specifications.

Confirming a carbon value for PYRAMAT® has been part of a 20 year process and it is today recognised as best practice for providing long-term water quality benefits.

All Propex TRMs use patented X3® fibre technology with a unique matrix of voids to promote revegetation and retain moisture. X3® fibre has superior UV resistance and offers enhanced performance in long term channel and slope protection.

Propex TRMS are supported by a free design software for both slopes and channels. Speak to our Tech Team today to see how PYRAMAT® can reduce your carbon footprint on your next project: gbs@globalsynthetics.com.au.