What is the problem?

An expansive subgrade consists of a highly plastic soil or clay that is prone to volume changes (i.e. expansion or shrinkage) due directly to variations in water content.

Expansive soils swell when exposed to large amounts of water and shrink when the water evaporates away. Because of this endless cycle of wet to dry conditions, the soil keeps in constant motion.

This causes significant geotechnical and structural engineering challenges to civil infrastructure built on this soil which can be very costly to repair or replace.

Expansive subgrades beneath sealed road pavements where this sinking and unevenly rising behaviour occurs (i.e. due to environmental loading) can create pavement cracks and failures – even without any trafficking on the pavement.

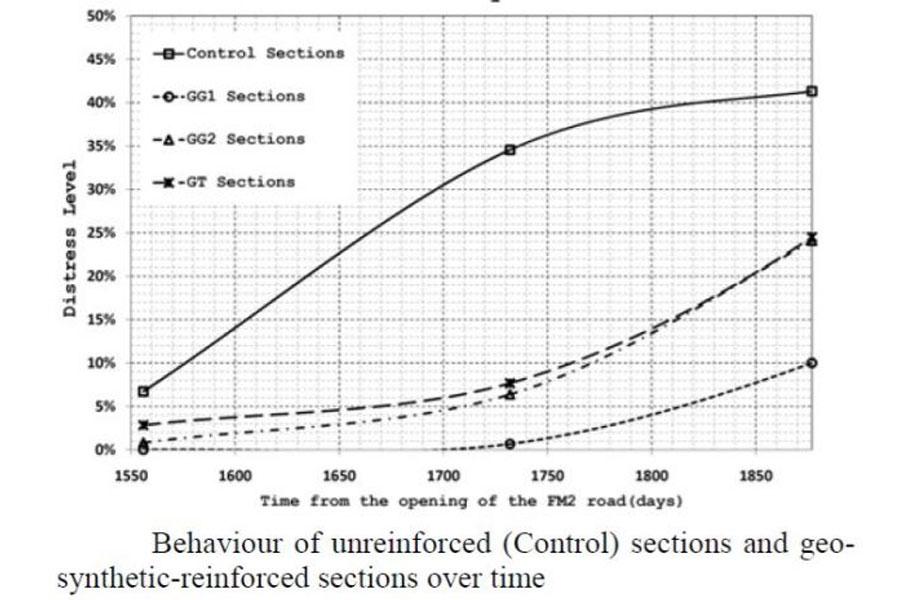

To overcome this, geosynthetic reinforcements such as Combigrid® geocomposites and Secugrid® geogrids have shown to be effective in the basal reinforcement and stabilisation of roads. In the last few decades, these geosynthetic reinforcement solutions have also been used to improve roads against environmental loading.

These solutions are not only cost-effective compared to other conventional solutions involving alterations of the expansive material, such as soil replacement or lime stabilisation, or controlling the subgrade moisture conditions – they are also environmentally sustainable and show more resilience according to full-scale field trials from around the world.

Roodi and Zornberg, 2012

Roodi and Zornberg, 2012

How does it work?

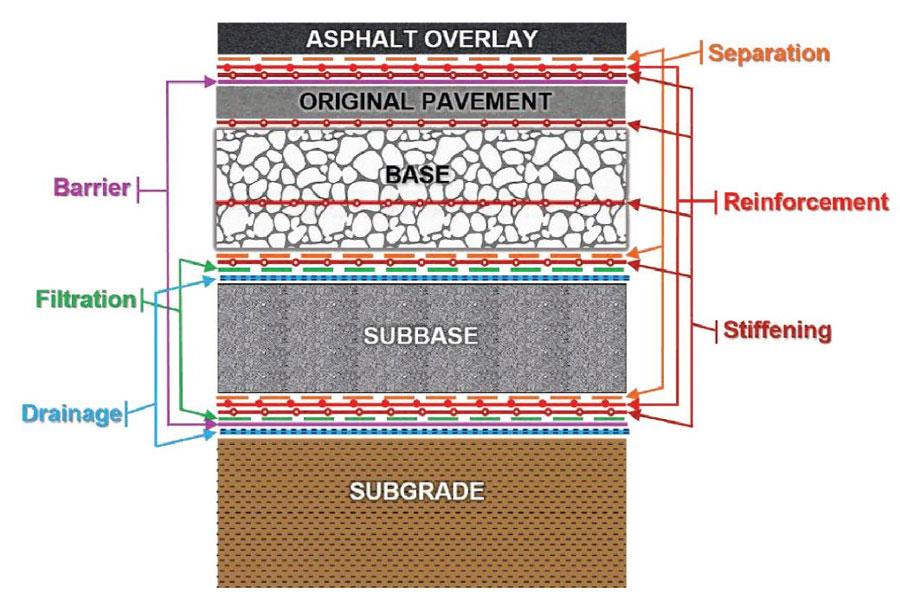

Geocomposites (geogrid + nonwoven geotextile) and geogrids used within pavement system layers fulfil a number of different functions that contribute to the good performance of road pavements. These functions include separation, filtration, lateral drainage, reinforcement, and ‘stiffening’ (Zornberg, 2017).

Geocomposites can provide a combination of all these functions whereas geogrids only provide the reinforcement and stiffening aspects.

The application of geocomposites and geogrids can provide significant benefits such as increasing the service life of road pavements and reducing pavement depths.

This is achieved by:

Mitigating reflective cracking in the asphalt overlay

Stabilisation/lateral confinement of the road base layer(s) to improve its stability/strength

Stabilisation/lateral confinement of the road soft subgrade to improve the bearing capacity and decrease the vertical stresses in the subgrade

Controlling the differential settlement to be more uniform and less severe

Separation of dissimilar material layers from intermixing

Filtration by allowing fluid to only pass while retaining fine particles

Lateral drainage by allowing fluid to flow within the plane of its structure

Zornberg, 2017

How to design sealed road pavements using Combigrid® and Secugrid® geosynthetics

Both Combigrid® geocomposite and Secugrid® geogrids have been independently tested and trialled, and successfully approved to increase the service life of road pavements and reduce pavement depths.

The design procedure for sealed road pavements with geosynthetics on soft and expansive soils needs to consider the following:

1. Design for traffic loads and bearing capacity

2. Design for expansive subgrade behaviour (i.e. delaying, minimising the severity and shifting/spreading longitudinal cracks)

The final reinforced thickness design is then chosen as the maximum of the two above cases, however, in the majority of cases, the design for expansive subgrade behaviour is the determining factor.

Simplified Design Steps

Bearing Capacity Design

a. Identify properties of the existing subgrade conditions (i.e. soaked CBR and swell). Note, where the subgrade exhibits a low value of CBR (CBR ≤ 3%), a separation/filtration/drainage layer (nonwoven geotextile) is required, together with the reinforcement layer (geogrid), so Combigrid® geocomposite is recommended in this situation.

b. Consider the geosynthetic reinforced semi-infinite subgrade layer (i.e. working platform) as the new subgrade and select the desired improved bearing capacity (i.e. presumptive CBR value) on the top of this layer using SecuCal® CBR software or manufacturer charts to determine the minimum required depth of gravel material above the geosynthetic material.

c. Design the remaining pavement layers (i.e. subbase/base/bituminous surface) using Austroads / Local Design Guideline empirical design charts or Circly® pavement design tool by using the new subgrade CBR value. The whole pavement thickness will be the summation of Steps b & c.

Consideration For Expansive Subgrade Behaviour Design

d. Consider Austroads / Local Design Guideline requirements for managing expansive subgrade movements (i.e. minimum cover depth requirements, adequate drainage measures etc.).

e. Also, consider investigations from field trials and long term monitoring during the last 20 years showing the effectiveness of geogrid reinforcement in helping to control the differential settlement and resulting pavement cracks on top of expansive subgrades. Research findings clearly suggest an optimum pavement design on soft and expansive subgrades can be achieved by firstly improving the subgrade bearing capacity using a geocomposite (such as Combigrid®) at the subgrade level for stabilisation and reinforcing the pavement but also using an additional layer(s) of geogrid (such as Secugrid®) within the unbound pavement layer for ‘stiffening’.

f. Modify the overall pavement thickness for geogrid reinforcement and stabilisation Please contact the Global Synthetics Technical Team for more information about this modification.

The Final Suggested Reinforced Pavement Design For Soft & Expansive Subgrades

g. Compare the above two (2) design procedures in selecting the optimum reinforced sealed pavement design.

Note: Where applicable, asphalt reinforcement geogrid composites such as Progrid® Compo GC or Progrid® Compo GB can also be used under or within an asphalt layer as extra insurance for extra control and delay of reflecting cracks.

The Pacific Motorway M1 North Upgrade project case study illustrates the effectiveness of asphalt reinforcements for crack mitigation and improving asphalt fatigue.

In summary, Combigrid®/Secugrid® geosynthetic reinforced structures have proven to be an effective total system providing a high level of safety for stability against soft and expansive subgrades, and stresses caused by both environmental loads and dynamic traffic loads.

For local project case studies illustrating the effectiveness of geosynthetics on soft and expansive soils please contact Global Synthetics Technical Team to obtain a copy.

To design your Combigrid®/Secugrid® reinforced pavement using SecuCal® CBR software, please click here to register. Our Technical Team is on hand to guide you through the software and design process if needed.

References:

Roodi, G. H., and J. G. Zornberg. 2012. Effect of geosynthetic reinforcements on mitigation of environmentally induced cracks in pavements. 5th European Geosynthetics Congress. Valencia 2012 Proceedings Vol 5. Topic: SOIL IMPROVEMENT AND REINFORCEMENT, pp. 611-616. Zornberg, J. G. 2017a. Functions and applications of geosynthetics in roadways: Part 1. Procedia Eng. 189 (Jan): 298–306. https://doi.org/10.1016/j.proeng.2017.05.048. Zornberg, J. G. 2017b. Functions and applications of geosynthetics in roadways: Part 2. In Geosynthetics, 34–40. Roseville, MN: Industrial Fabrics Association International.