The efficient use of Combigrid® geocomposite and Secugrid® geogrid led to a more economic design and enabled a safe working platform on a poor subgrade conditions, coupled with high working loads. The original design had specified a single layer of 100 kN/m ultimate strength biaxial geogrid with about 800mm thick platform.

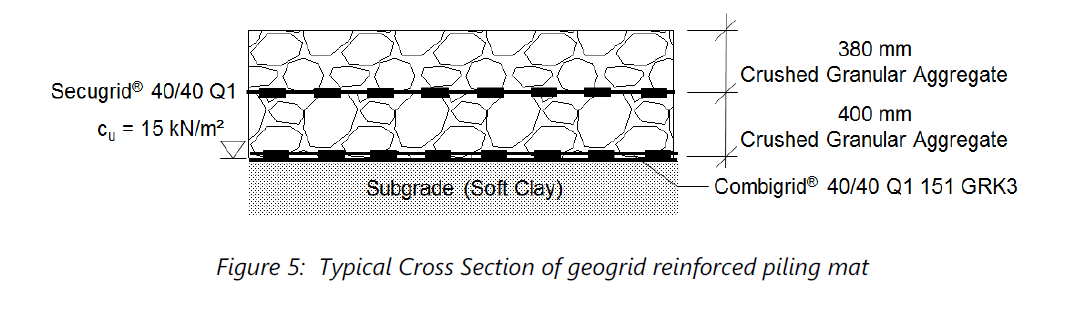

The high stiffness of Combigrid® geocomposite and Secugrid® geogrid enabled the design to be changed to an efficient and economical alternative design of 80kN/m geosynthetic and 780mm thick platform. For construction on soft soils, Separation is required as well as reinforcement. A nonwoven geotextile is usually used to separate the granular material from the soft subgrade and a geogrid is used to reinforce the granular material and increase the confinement and so the stiffness of the granular layer. The geosynthetic material used in this project included a layer of Combigrid® 40/40 Q1 geocomposite on top of the existing subgrade and a layer of Secugrid® 40/40 Q1 geogrid in the middle.

Combigrid® is the combination of Secugrid® geogrid and an integral nonwoven geotextile. This geocomposite is suitable for construction on soft soils where both geogrid and geotextile are required. Combigrid® saves construction costs and time by having the benefits of two products all in one product. As the geotextile is integrated in between the geogrid bars, there is no risk of delamination and an improvement will occur in the performance of the platform compare to separate geogrid and geotextile systems or the geogrid with attached geotextile. It also makes the installation process easier and faster, without the risk of recoil due to its flat structure.

By using the high Combigrid® and Secugrid®, the client could achieve a considerable saving in this project by using less granular material and a lighter geosynthetic product.