A Guide To Successful Geosynthetic Reinforced Asphalt Overlays

Roads and pavements are constantly under stress from heavy vehicles and increasing traffic volumes as our cities become more congested. When this stress combines with temperature fluctuations and environmental movements, reflective cracking can begin to occur in asphalt surfaces. In turn, water finds its way into these cracks which speeds up the deterioration of the pavement, creating the need for asphalt maintenance and rehabilitation.

To inhibit these cracks and to reduce the ongoing maintenance requirements of asphalt surfaces, geogrids and geogrid composites can be used to add additional strength and reinforcement to asphalt layers.

Furthermore, to extend the life of assets such as roads and freeways, geogrids and geogrid composites can be used to delay the onset of reflective cracking as well as to the reduce the magnitude and severity of these types of cracks. High strength geogrids and geogrid composites such as ProGrid® can help reduce the stress on the asphalt layers and provides a reliable reinforcement benefit to the asset.

About ProGrid® Asphalt Reinforcement

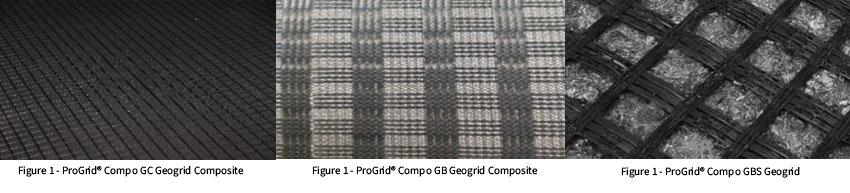

ProGrid® asphalt reinforcement geogrids can be made of either a high modulus polyester (PET) or glass fibre geogrid, and both are produced with a modified pitch coating to provide a good bond with the asphalt layers. When combined with an integral permanent light weight PET geotextile fabric backing (which is fully stitch bonded) it creates a geogrid composite such as ProGrid® Compo GC geogrid composite (Figure 1) or ProGrid® Compo GB geogrid composite (Figure 2) which then provides addition construction benefits for easier installation and lesser wrinkles.

Further to the above, ProGrid® glass fibre geogrids can also be produced with a self-adhesive backing called ProGrid® GBS geogrids (Figure 3).

Generally, ProGrid® asphalt reinforcement are designed to increase the tensile strength of the asphalt layer and extend the service life of pavement layers, as well as decreases the occurrence of reflective cracking under cyclic traffic loads.

With a high modulus, high temperature resistance and high bonding properties, ProGrid® asphalt reinforcement can be used with asphalt overlays in new roads or rehabilitation works as reinforcement or as an asphalt interlayer.

Asphalt overlays – Getting the basics right during installation!

Successful geosynthetic reinforcement of asphalt overlays are typically dependant on good installation techniques. The full installation guide for ProGrid® asphalt reinforcement products can be found under the technical resources section on the Global Synthetics webpage however the key points include:

Storage and Handling

Surface Preparation

Bonding Coat and Application

Installation / Placement

Joints and Overlapping

Asphalt Placement

Damage and Replacement

Ultimately, the surface preparation is key, including using an appropriate bonding seal, asphalt mixture ratio, particle size, and ensuring proper compaction. ProGrid® asphalt reinforcement products perform best when installed in accordance with the manufacturer’s guidelines, project specifications, and individual site conditions – and of course, if in doubt, seek engineering advice from Global Synthetics professional staff.

As an additional guide for the selection, design, and installation of asphalt reinforcement products. Global Synthetics has created a ‘General Checklist for AC Geosynthetic Overlay Placement’ document to help in this process and can be found here.

For support and engineering advice on how to extend the life of asphalt pavements with ProGrid® asphalt reinforcement products, get in touch with the technical team at Global Synthetics.