Project: New Drainage Channel Solves Road Flooding in Local Council

Date: Oct 2021 – April 2022

Location: Far North QLD

Product: ArmorMax® 75, Combigrid 3030

PROJECT BACKGROUND

This project was conducted on an island off Far North Queensland, to replace an existing channel which had been experiencing prolonged issues. The channel was made of sands, that were maintained and shaped to catch the surface water runoff from the nearby hills.

The channel was situated between domestic properties on one side, and a main road on the other side.

PROBLEM

The existing channel had two main issues that needed to be addressed. The first issue was the ongoing maintenance required by the local council. This included digging out the silt formation and maintaining the shape of the channel to control the water.

In addition to the maintenance, the second issue was that the channel would often collapse due to the dispersive soils, causing the surface water to overflow onto the main road beside it. This was especially problematic during the wet season, as the roads were too difficult and dangerous for local people to use.

SOLUTION

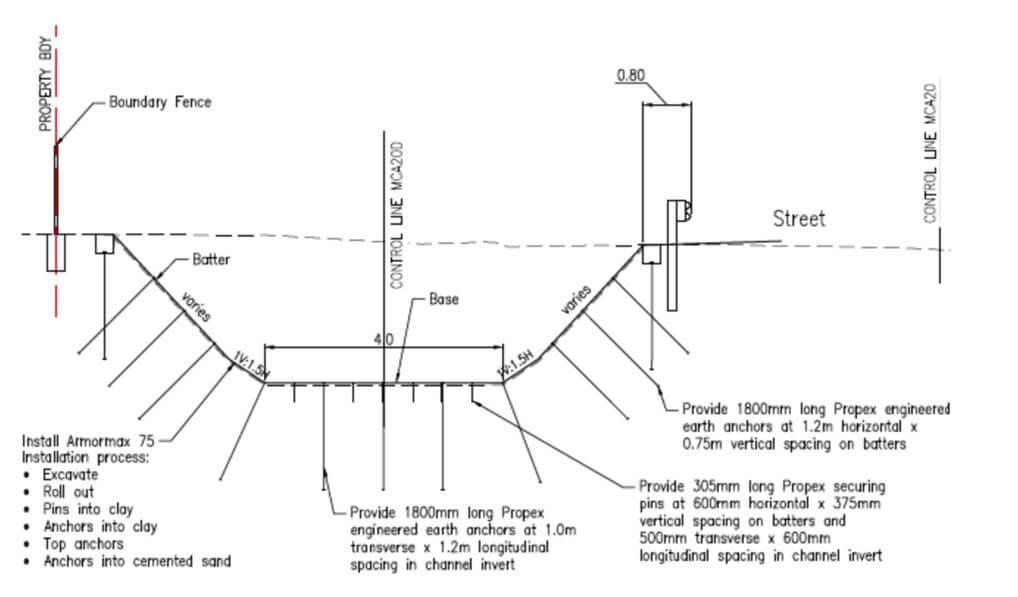

After reviewing the volume of water that can be generated during the wet season, and running the calculations through Propex EC Design software, a new channel was designed. The goal of this channel was to remove the need for continuous maintenance, uphold its shape and structure, and ensure water was controlled and would not overflow onto the road.

The new channel has 1:1 batters up to 4m, and a 3.5m flat base. To work with the dispersive sands, the ArmorMax® system was designed and installed over several months due to the weather. The system consisted of Geofirma® Non-Woven geotextile, and Pyramat® 75 High Performance Turf Reinforcement Mats (HPTRMs), secured with procession anchors.

The Geofirma was laid on the dispersive sand to keep it in place while still allowing water through. This was followed by the Pyramat HPTRM, due to its 75-year design life and UV resistance. These materials were secured in place by using 3m-long percussion anchors with the B3 sized head, to keep it all locked and tensioned against the batter. The anchors needed to be 3m long to find a clay base with suitable CBR to tension and lock the anchors in place.

In the base of the channel Combigrid® Composite Geogrid was installed to further provide filtration and separation, while also adding reinforcement. Like the batters, Pyramat was installed over the top and secured with anchors.

RESULTS

The end result of this project is a fully lined channel with the Armormax system, with stabilised embankments to keep the shape and integrity of the channel. There is also a reinforced floor for the local council to access the base of the channel if the need arises.

The most important aspect of this project was keeping the water off the road. This solution, with a system designed to last for up to 75 years, will function to improve safety conditions for the locals.