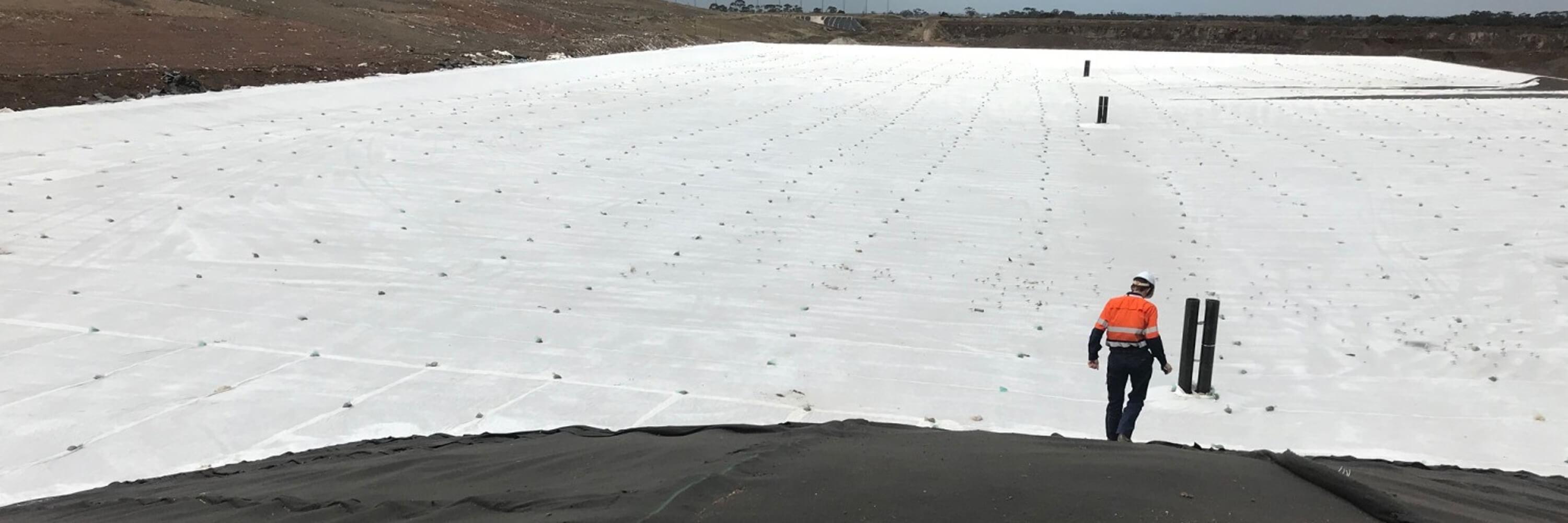

Melbourne Regional Landfill (MRL)

TRANSNET Drainage Geocomposite & GEOFIRMA Cushion and Filter Geotextiles

The Problem

Melbourne is one of the fastest growing Australian cities. Upgrading infrastructure to support this rapid growth is essential. The MRL meets a critical infrastructure need, to deal with the city’s ever-increasing residual waste today, and for the long term. There is a need for residual waste to be managed safely and effectively through Best Practice Environmental Management (BPEM) design guidelines set up by the local EPA regulatory authority. Global Synthetics were able to supply geosynthetics that complied to design specifications and met critical quality assurance hold points including MQC & CQC testing.

The Solution

80,000 m2 of GEOFIRMA® AS540E cushion and protection fabric and GEOFIRMA® AS200B filter geotextile were supplied. A TRANSNET® TN350-1-200 drainage geocomposite was used as part of the leachate collection system on the side walls of the new landfill cell. An appropriately designed geonet drainage geocomposite was used as an alternative to the gravel drainage layer the landfill sidewall leachate drainage systems. Geocomposite drains are permitted to also be used in secondary leachate collection systems (leak detection systems) and groundwater drainage systems.

The TN350-1-200 is a geocomposite with a 8.3mm thick HDPE heavy duty geonet core with a 200g/m2 geotextile thermally bonded to it.

The geonet drainage geocomposite should:

have an internal geonet drainage core manufactured from virgin high-density polyethylene (HDPE)

have a geotextile fabric heat bonded to the upper surface of the geonet to prevent fines from entering the drainage channels, and a geotextile fabric heat bonded to the lower surface to prevent damage to adjacent geosynthetic layers

be able to resist degradation caused by factors such as chemical attack, temperature, hydrolysis and stress cracking over the entire life of the landfill. Polypropylene geotextiles are chemically more resistant and preferred for this reason.

have high ply adhesion and interface friction with adjacent layers. For this reason the geocomposite geotextile must be thermally laminated to the geonet core. Gluing is not recommended due to poor strength and durability concerns.

have adequate long-term flow capacity for the calculated leachate flow rate at the site. The allowable flow rate should be determined from a long term 100-hour test simulating field conditions (adjacent layers, waste loads and hydraulic gradient). This test will account for decreases in flow capacity due to intrusion of the geotextile into the geonet core.

The designer should then allow for factors that will further reduce the thickness and capacity of the drainage core under long-term field conditions. These factors include long-term creep deformation of the geonet, and chemical and biological clogging caused by leachate. In addition to these specific reduction factors, adequate general safety factors should be applied to account for overall design uncertainties.