The Project

Grindleford Drive, located in the developing suburb of Balcatta in Perth, is a low-lying road that traverses marshland composed of silty sand and organic materials. Due to its unique location, the pavement of Grindleford Drive was prone to issues such as differential settlement and insufficient bearing capacity. The City of Stirling required a solution that would improve the stability and strength of the road while being cost-effective and easy to install.

The Challenge

The primary challenge faced in this project was the poor subgrade condition, resulting from the marshland underneath the road. The silty sand and organic materials did not offer sufficient bearing capacity, making it difficult to achieve the necessary compaction and pavement stability. Additionally, the subgrade's low California Bearing Ratio (CBR) made it more challenging to enhance the pavement's strength.

Our Solution

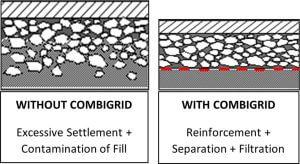

Combigrid® has become the go-to product for many municipalities and road authorities to improve pavement strength. Combigrid® is a unique product in the marketplace as it provides reinforcement and separation in the one product.

Typically, a geotextile on its own is utilised to provide separation between subgrade and engineered fill to avoid intermixing of materials, however if sufficient stiffness or compaction isn’t achieved due to a poor subgrade CBR, then a composite geogrid is used to increase the strength of the pavement, much like steel reo bar in concrete.

One of the main benefits of using a product like Combigrid® is that it allows the reduction of engineered backfill in pavements, which was a true cost saving for the City of Stirling.

Other benefits of Combigrid® include:

Technical performance: greater modulus against other geogrids (tensile vs strain), which leads to better effective increase in subgrade bearing capacity and correspondingly lower rutting at the pavement surface. Combigrid® carries better installation damage resistance than other geogrids.

Roll width: widest rolls on the market, enabling significant savings in overlap wastage. Working platform: provides an instant working platform for access to plant over very weak subgrades. A geotextile placed on its own does not provide a working platform over marginal subgrades.

Ease of installation: Combigrid® is easy to handle on-site due to its low memory and ease of cutting. Transport costs: its low profile requires only 1/3rd of the truck space compared to bulky extruded materials.

Proven track record: millions of m2 of Combigrid® have been installed across Australia for basal reinforcement, much of that for state road agencies and local government applications.

German Quality Control: manufactured under strict ISO certification with guaranteed compliance to published data. Each roll is traceable, and test reports can be made available to the client at any time.

Overall, the City was pleased with the performance, ease of installation and cost benefits that Combigrid® delivered.