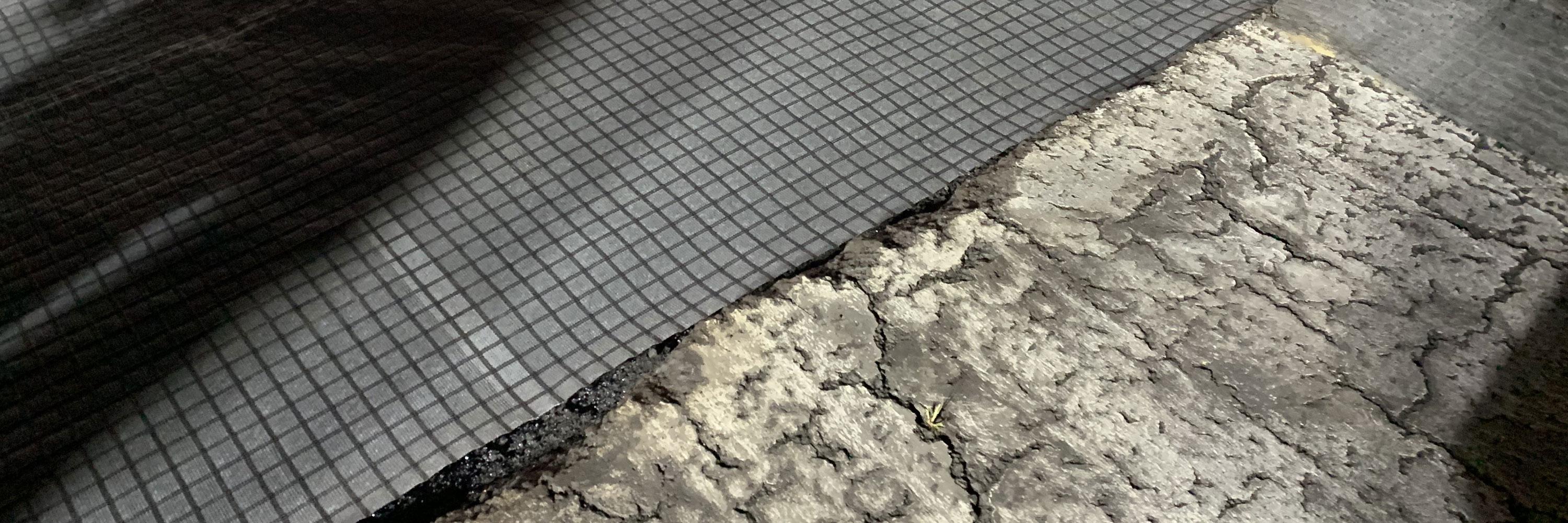

What is the Problem

Is reflective cracking in your asphalt road pavements keeping you up at night? Road pavements are constantly under stress from heavy vehicle loads, temperature fluctuations and environmental movements. These types of influences are the leading causes to the occurrence of cracks appearing on your asphalt surfaces. In turn, water will find its way into these cracks and accelerate the deterioration of the pavement, creating the need for early maintenance intervention and rehabilitation at a cost to the asset owner.

What is the Solution

The main function of geosynthetics used in the construction and rehabilitation of roads and pavements subjected to thermal, fatigue and reflective cracking is to reduce the amount of cracking in a new pavement or asphalt overlay. In addition, a stress relief layer and/or a barrier to top-down water ingress into the subbase and/or subgrade may be provided if a geocomposite is used.

To manage these cracks and extend the life of the pavement. The use of geogrids, geocomposites and geogrid composites can do exactly that to delay the onset of reflective cracking as well as to the reduce the magnitude and severity of these types of cracks.

High strength geogrids and geogrid composites such as Global Synthetics, ProGrid® asphalt reinforcement products range can help reduce the stress on the asphalt layers and provides a reliable reinforcement benefit to the asset.

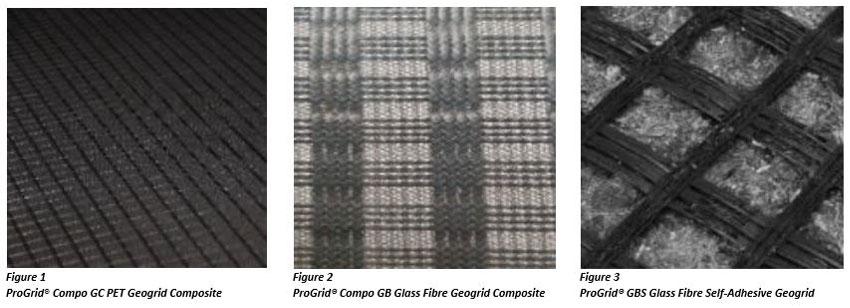

ProGrid® asphalt reinforcement geogrids can be made of either a high modulus polyester (PET) or glass fibre, and both are produced with a modified pitch coating for chemical resistance and to provide a good bond with the asphalt layers. When combined with an integral permanent light weight PET geotextile fabric backing (which is fully stitch bonded) it creates a geogrid composite such as ProGrid® Compo GC PET Geogrid Composite (Figure 1) or ProGrid® Compo GB Glass Fibre Geogrid Composite (Figure 2) which then provides addition construction benefits for easier installation and lesser wrinkles.

Further to the above, ProGrid® Glass Fibre Geogrids can also be produced with a self-adhesive backing called ProGrid® GBS Glass Fibre Self-Adhesive Geogrid (Figure 3).

Generally, ProGrid® asphalt reinforcement is designed to increase the tensile strength of the asphalt layer(s) and extend the service life of pavement layer(s), as well as decreases the occurrence of reflective cracking under cyclic traffic loads.

With a high modulus, high temperature & chemical resistance, and high bonding properties; ProGrid® asphalt reinforcement can be used with asphalt overlays in new roads or rehabilitation works as reinforcement or as an asphalt interlayer.

All Global Synthetics, ProGrid® asphalt reinforcement products range fully comply to the Queensland Department of Transport and Main Roads (QTMR) Technical Specifications, MRTS104 and have been used extensively on roads projects all over Australia and overseas!

For support, engineering advice and training on how to extend the life of asphalt pavements with ProGrid® asphalt reinforcement products, get in touch with the technical team at Global Synthetics.