Case Study: Controlling Reflective Cracking

Project: Deception Bay & Morris Rd, Rothwell Intersection Upgrade

Date: May 2020 – September 2020

Location: Deception Bay & Morris Road Intersection, Rothwell, Queensland

Product: Progrid® Compo GC 50/50 (Asphalt Reinforcement Geocomposite)

Project Background

The Queensland Department of Transport and Main Roads (TMR) recently completed construction on a $7 million project to improve traffic flow and reduce congestion on Deception Bay Road between Anzac Avenue and Morris Road intersections. The $7 million upgrade will widen Deception Bay Road, providing an additional northbound and southbound lane through this section. The extra lanes on Deception Bay Road will increase capacity and efficiency through this busy location as well as reduce congestion at Morris Road and Anzac Avenue intersections.

Problem to be addressed

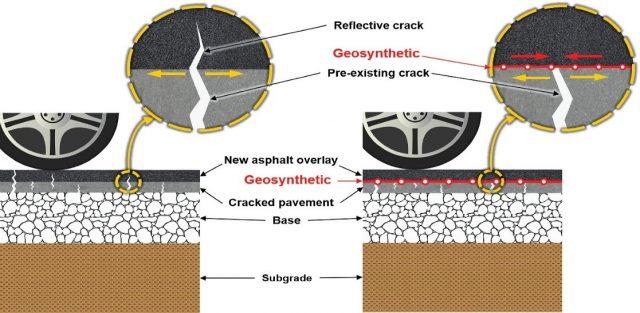

Due to increasing traffic flow and heavy vehicle loading on the road coupled with daily and seasonal temperature variations, the road pavement is impacted by higher stresses leading to the development and propagation of reflective cracking in the asphalt concrete layers. These cracks will begin to affect the structural integrity of the pavement and also allow the infiltration of moisture resulting in the deterioration of the pavement, bringing forward earlier maintenance intervention or deep strength rehabilitation works.

These types of pavement treatment activities are not only expensive for the asset owner but also causes major disruption to the community and road users. Using innovative technological solutions in the road building materials is one way to help improve and extend the asset life and to delay these treatments. When constructing new asphalt concrete pavements and/or asphalt concrete overlays, consideration needs to be given to delaying the onset and propagation of reflective cracking.

Innovative Solution

Aside from the conventional use of polymer modified binders, the use of asphalt reinforcement geogrids / geocomposites can be implemented for little additional cost which can bring about considerable cost savings over the life of the pavement asset.

Image Source: Dr Zonberg

Global Synthetics were contacted to provide technical assistance in selecting the most suitable asphalt reinforcement geosynthetic product to reduce / inhibit reflective cracking and extend the fatigue life of the asphalt concrete layers. The asphalt reinforcement geosynthetic is to be an approved product meeting the TMR Technical Specification MRTS104 – Retarding Pavement Reflective Cracking using Asphalt Geosynthetics.

Global Synthetics specialist technical engineer met with the awarded civil and asphalt contractors to review the project details. Taking into consideration the history and source of the pavement failures, the proposed pavement design, configuration of the new road alignment, technical and construction requirements ensured the selection of the correct geosynthetic product to provide the best outcome for the project and future pavement performance.

The approved TMR pavement design consisted of a full depth asphalt pavement (FDA) for heavy-duty applications incorporating an asphalt reinforcement geosynthetic approximately 180mm below the final finished surface level and located within the EME2 high modulus asphalt base course layer.

Global Synthetics provided an asphalt reinforcement geosynthetic solution with Progrid® Compo GC 50/50 Geocomposite.

Progrid® Compo GC 50/50 Geocomposite is a combination of a high strength Polyester (PET) geogrid with a fully stitch bonded permanent light-weight porous PET geotextile fabric backing with a minimum mass of 80 g/m2 complying to MRTS104 geocomposite requirements for better installation, less wrinkles, better intimate bonding contact, and reflective cracking performance.

Installation - Features and Benefits

The installation of asphalt reinforcement geosynthetic products is very important in their performance. It is very sensitive to various parameters, which can vary depending on site, such as product, weather, surface condition, bonding material etc. Manufacturers installation guidelines should be adhered to completely and carefully.

Global Synthetics not only supplied the asphalt reinforcement geosynthetic product but also provided complimentary onsite project support during installation. As part of the prestart meeting for each shift, Global Synthetics technical engineer collaborated with the installation contractors to run through the manufactures installation guidelines and to discuss the construction processes for the shift ahead. If required, tailoring the installation procedure to satisfy the construction needs without compromising the product performance.

The installation of Progrid® Compo GC 50/50 Geocomposite was successfully completed for the project and prior to asphalt concrete placement at the end of each shift without any delays. The overall feedback from construction staff and the client representatives onsite was the engineering support and collaboration on site was exceptional, the product is easy to handle, the product installed with lesser wrinkles, and provided better bonding compared to other available products with an ultra-light geotextile backing or a geogrid alone.

Progrid® Compo GC 50/50 Geocomposite features:

High strength and high temperature resistant.

Increases the fatigue resistance of the asphalt layer, decreases the occurrence rate of reflective cracking under cyclic traffic loads, and extends the service life of pavement.

Bituminous coating and 80 g/m2 porous geotextile fabric backing provides better bonding and lesser wrinkles.

Easy to handle and robust against installation damage.

Global Synthetics supplies a wide range of asphalt reinforcement products which provides the opportunity to designers and contractors to select the most suitable product for their application:

Asphalt Reinforcement Geocomposites

ProGrid® Compo GC 50/50 and 100/100: Polyester (PET) geogrid with a PET nonwoven light-weight geotextile backing (50 – 150g/m2).

ProGrid® Compo GB 50/50 and 100/100: Glass Fibre geogrid with a PET nonwoven light-weight geotextile backing (50 – 150g/m2).

Asphalt Reinforcement Geogrids

ProGrid® GC 50/50 and 100/100: Polyester (PET) geogrid.

ProGrid® GB 50/50 and 100/100: Glass Fibre geogrid.

Stress Absorbing & Waterproofing Paving Fabric

ProFab ProPave®: Polyester (PET) nonwoven geotextile paving fabric.

Crack & Joint Sealing Self-Adhesive Tape

ProTac®: Polyester (PET) nonwoven stress absorbing membrane strip.

Choosing the right asphalt reinforcement geosynthetics for your application will depend on a range of factors. For assistance in choosing the right product for your individual project, contact the specialist engineering team at Global Synthetics.