Case Study: Combigrid® Hardstand in Brisbane

Location: Brisbane QLD, Australia

Products: Combigrid® & Secugrid®

General Information

In 2011, TRANSCITY was selected as the contractor to design, construct and operate the Legacy Way Toll Road in Brisbane’s west. Legacy Way, once complete, will connect the Western Freeway at Mount Coot-tha with the Inner City Bypass at Kelvin Grove.

The Legacy Way Toll Road is an initiative of the Brisbane City Council and intends to reduce travel time between the Centenary Bridge and the Inner City Bypass and reduce traffic on the Milton Road and Coronation Drive. It is scheduled for completion in 2014.

Project/Problem Description

The project involves construction of a 4.6 kl road tunnel using a combination of tunnel boring machine (TBM) and cut and covers techniques. The road tunneling is completed with the installation of precast concrete tunnel segments. The precast concrete segments weigh some 8 tonnes each and were to be stacked 9 units high stabilised on concrete feet and separated by two support beams.

Each stack of precast concrete tunnel segments weighed some 70 tonnes spread over the two concrete feet creating a normal pressure of more than 400kPa. Combined with the dead load of the concrete segment stacks the solution also needed to consider the live load of a 16 tonnes forklift truck used to stack the segments. Limited depth was available for placement and compaction of the granular pavement and the subgrade was a relatively weak 2% CBR at the selected location for the hardstand pavement.

Solution

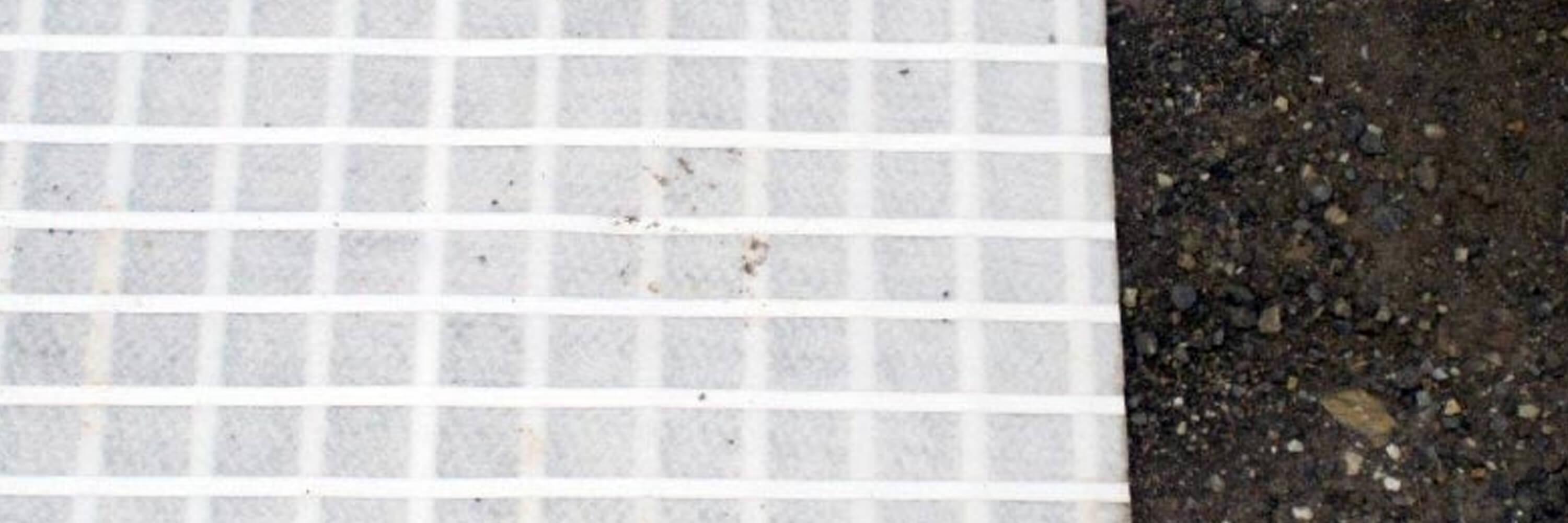

“Global Synthetics” were contacted to provide assistance in strengthening a granular pavement suitable for stacking of the precast units. To overcome this, Global Synthetics provided a solution to the client adopting 2 layers of geosynthetic reinforcement to stabilise the subgrade and support the imposed loads of the precast concrete units. The product selected at the subgrade interface was the Combigrid 40/40 Q1 Geocomposite which consists of a Secugrid® geogrid as the reinforcement component; with an integral needle-punched nonwoven geotextile firmly welded between the reinforcement bars for separation/filtration purpose.

Combigrid® provides a reinforcement function to the pavement as well as a separation function by way of the unique integral geotextile. The separation function ensures that the imported pavement gravels do not mix with the fine grained subgrade soils, reducing the risk of weakening the reinforced base course over time. The solution also required a second layer of geogrid installed midway in the reinforced base course section to provide additional reinforcement and support. The geogrid adopted was Secugrid 40/40 Q1 which is a welded Geogrid with a high stiffness and low installation damage. The pavement was completed in late 2011.

Results

Combigrid® Geocomposite increased the bearing capacity of the existing soft soil and provided a suitable hard stand for the extreme loads. Combigrid® combines reinforcement, separation and filtration into one single product. It offers the advantages of two materials with the simplicity of installing a single product thus reducing supply and installation costs considerably.

It is also extremely quick and easy to install. The Secugrid® welded geogrid with rigid bars ensures the safe reinforcement with a high performance and long design life due to high stiffness in all directions and low installation damage.