Government data suggests that there are around 500 officially registered landfill sites in Australia. Although this number is declining, the average size of each site is increasing. Approximately 75% of garbage in Australia goes to just 38 sites1. To effectively manage the by-products of these landfill sites as the waste degrades and decomposes, the resulting leachate needs to be trapped, managed and diverted.

Leachate is the liquid that has percolated through the permeable material, which can contain all manner of contaminants and particles. Because of this contamination, it cannot be released directly into the environment, and leakage of this liquid or slurry into the surrounding areas is controlled by strict regulations. For a landfill facility to function efficiently during its lifetime, the contaminated leachate that is produced must be collected and removed effectively.

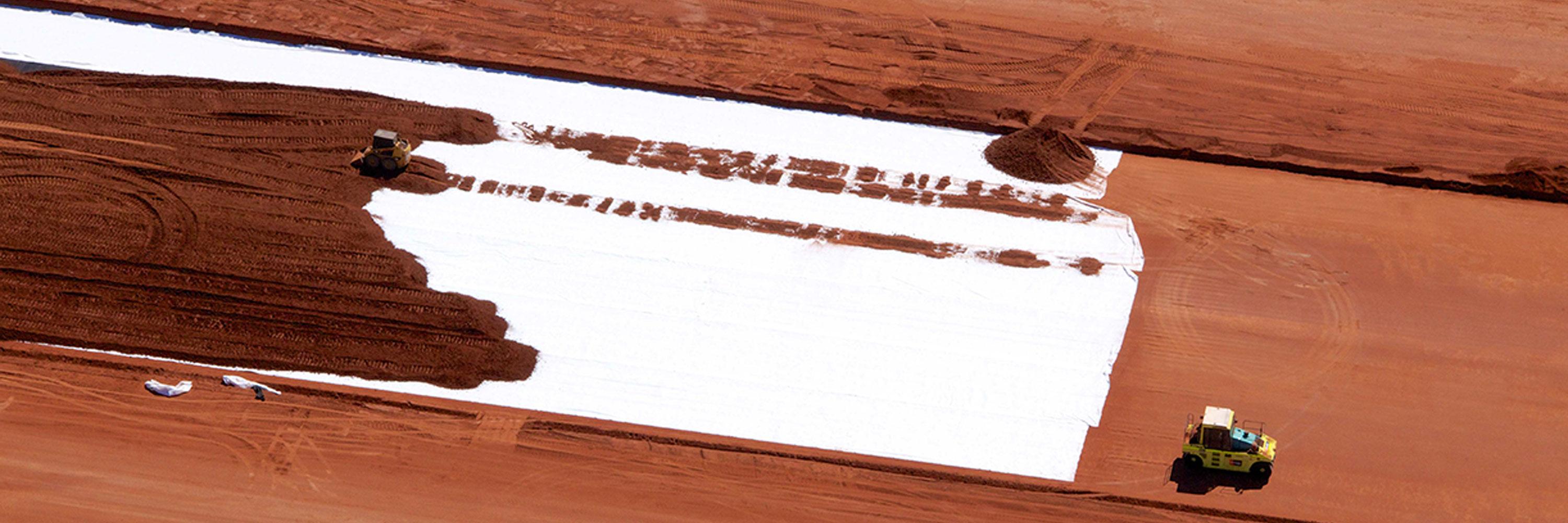

Additionally, leachate can be found in other industrial processes such as in mining where tailings ponds are constructed to contain chemical or biological threats to the environment.

How is leachate removed from a landfill site?

Preventing environmental contamination is a major hurdle that landfill owners must overcome. This is amplified even further for landfills that contain hazardous waste. In light of this, leachate collection systems are designed in landfills to remove the leachate for treatment, disposal, or recirculation. Additionally, they help to control the head of the leachate on the liner system, which minimises the quantity of leachate seeping out of the system.

Geonets are rapidly becoming one of the most commonly used drainage materials in the leachate collection and removal systems of landfills. This is because they are a cost-effective and easy to install alternative to traditional stone or aggregate drainage collection systems.

A geonet is a geosynthetic material similar in structure to a geogrid, consisting of integrally connected parallel sets of ribs overlying similar sets at various angles. Made from HDPE, the ribs are arranged to provide high tensile strength and resist compression under load. The resulting grid functions as an in-plane drainage system for liquids or gases.

These products are sometimes bonded with geotextiles on one or both sides, turning them into what is known as a drainage geocomposite. Geonets are also particularly useful in solving the challenge of slopes which are so common in landfill operations.

Which geonet is best for leachate management?

There are two common types of geonets, bi-planar and tri-planar, referring to their rib structure and how they channel away liquid. The choice of which is best depends on the requirements of the particular site.

Although both types of geonets are formed by a continuous extrusion process into a netlike configuration of ribs, the way they direct the flow of liquid is different. The bi-planar type encourages liquid to flow through and around these ribs in a relatively even pattern. The tri-planar geonet, on the other hand, has a wider flow channel that encourages both an even flow pattern combined with a directional flow away from the area.

How bi-planar geonets work

Transnet® Bi-Planar Geonets have a core profile described as bi-planar. The structure of the geometry of the ribs is quite simple. The major feature of the rib design is that the Transnet® geonet drainage core allows relatively radial flow in all directions of the product.

This drainage feature is important in relatively flat drainage applications such as the base of a landfill or a leachate pad in mining applications. They are ideal for many flat planar structures that may be subject to differential settlement. A designed drainage grade may be compromised by ground settlement, so it is important that the drainage function of the product is maintained in spite of changes to predetermined grades.

How tri-planar geonets work

Tri-planar geonets consists of two layers of parallel ribs with a small cross-section area. These are separated by thick vertical ribs with a large cross-section area. When meshed together, this structure creates a wide flow channel.

It is critical when using these nets that the direction of placement is always carefully considered and always with the machine direction of the roll placed in the direction of the required flow. This will ensure the channelizing effect is maintained and that the leachate is funnelled appropriately into the collection tank or treatment area.

How to choose a geonet

Choosing the right geonet for your application will depend on the gradient of the site, the overall load and a range of other factors. For assistance in choosing the right product for your individual project, contact the specialist engineering team at Global Synthetics.