Case Study: Bentofix® Soil Contamination

Construction Date: 2003

Location: Germany

Products: Bentofix® BFG 5000, Secudrän® R 201 WD 601 R 201, Secugrid® 200/40 R6, Secugrid® 300/40 R6

General Information

When constructing or extending new roads, the responsible designers and contractors are increasingly faced with the task of preventing soil contamination. Therefore, measures for the protection of the groundwater are necessary in more and more cases. The corresponding requirements and specifications for such measurements are regulated in the "guide-line for constructional measurements of roads in water protection areas" (RiStWag, edition 2002) in Germany. Besides the constructional specifications for building materials and methods and the constructive design of the various road areas, special attention is paid to reliability and security of barrier systems.

These systems have the task to protect the underground and the groundwater by retaining contaminating substances from road traffic. In more and more cases, experts refer to the application of geosynthetics considering practical and economic aspects in building construction. These materials hold off unwanted residues and also provide high performance and low costs. They are easy to handle and ensure high validity and security. Therefore, Carbofol® geomembranes and Bentofix® geosynthetic clay liners are increasingly used in road construction. The construction planning of the new by-pass road B 82n from Goslar to the highway A7 also required a groundwater protection measure. In the area of the village Astfeld, area Herzog Julius Hütte, the planned road leads across a 250 m long and 500 years old waste dump.

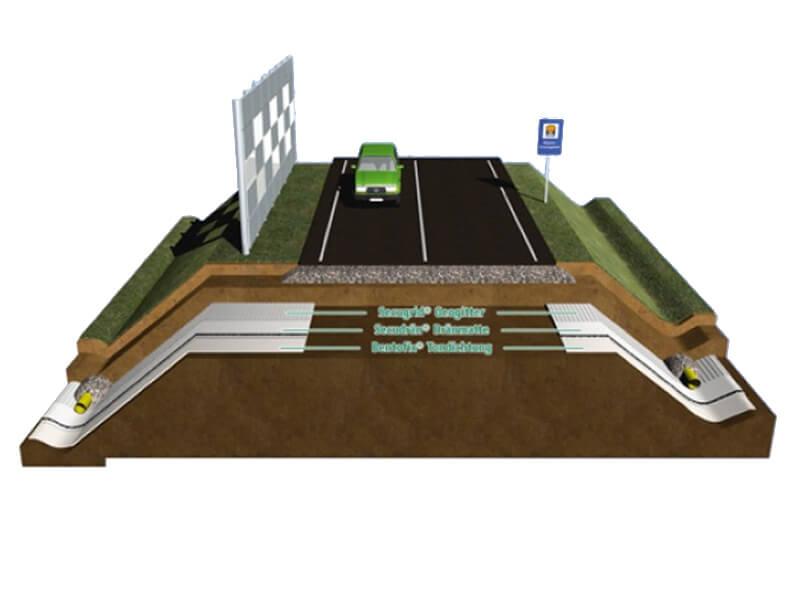

The bottom soil layers consist of smelter slag and were considered as contaminated. The official plan approval for the road B 82n stipulated a sealing in order to prevent surface water from penetrating and washing out pollutants into the groundwater. Considering various solutions, the regulators finally decided to install a GCL (geosynthetic clay liner) as sealing element.

According to the calculations of the design office BBU in Braunschweig and the Bauberatung Geokunststoffe (BBG) of Lemförde (construction consultant for geosynthetics), the application of a geosynthetic drainage mat above the GCL was recommended thus preventing water pressure build-up and the reduction of soil strength. Additionally, a geogrid with high strength junctions was placed in several slope areas allowing a steeper and low cost construction. As a result of detailed tests, the GCL Bentofix® BFG 5000, the drainage mat Secudrän® R 201 WD 601 R 201 and the Secugrid® 200/40 R6 and 300/40 R6 from Naue Fasertechnik GmbH & Co. KG were chosen as the geosynthetic elements. The result is convincing: The regulators have highly been satisfied about the planning and the performance of the project as well as about the quality of the applied materials.

On behalf of the city council, another project simultaneously started (the sealing of a boundary dam in the border area of the road B 82n) according to the regulations of RiStWag and using the products of Naue Fasertechnik.