Case Study: Bentofix® Pipe Jacketing

Construction Date: 2002

Location: Bad Elster, Germany

Products: Bentofix® BFG

General Information

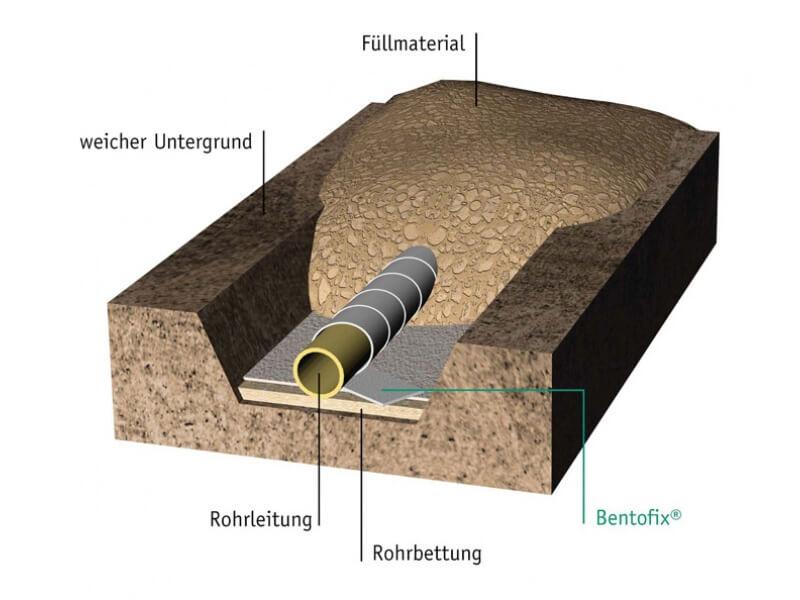

The City of Bad Elster, Germany resolved to put in new sewage lines. Since this construction project was within a category II medical water preservation zone (pursuant to RiStWag 2002), secondary protection for piping was necessary to protect medical water in the area.

This meant either employing double-walled pipe with all its cost-intensive overhead or jacketing a single-walled pipe with a sand/bentonite mixture at least 25 cm thick - a procedure requiring a lot of work effort. Working together with local engineering offices, NAUE came up with a long-lasting, economical alternative. Pipe jacketing made of Bentofix® BFG 5000 geosynthetic clay liners (GCL) was proposed.

This system employs bentonite atting whose encapsulated bentonite powder absorbs liquids in the event of a pipe leak, causing it to swell and thereby seal the leak. These characteristics make bentonite matting act as a secondary protection system.

Since the nonwoven upper surface of Bentofix® is filled at the factory with sodium bentonite, all overlapping areas are self-sealing on contact with water. This eliminates cost and time expenditures at the construction site to seal overlaps.

These advantages convinced planners to the point that even future new lines and refurbishing work is also to be carried out with this system.