Case Study: Bentofix® Canal Sealing

Construction Date: 2001

Location: Dortmund-Ems-Kanal, Deutschland

Products: Bentofix® BZ 13-B

General Information

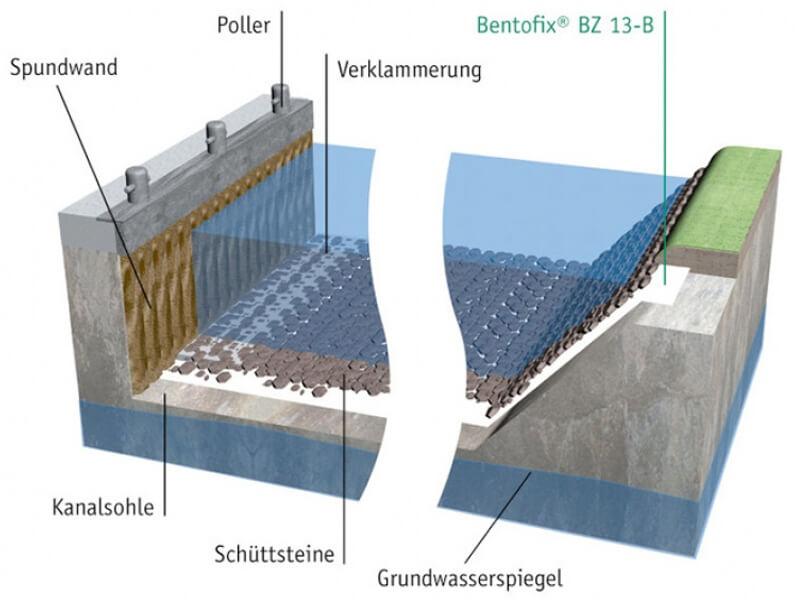

After the first pilot project installation of a geosynthetic clay liner (GCL) in a 1 km long section of the Havel-Oder-Waterway in 1997/98, approved by the local German Water and Ship Authority a second project followed shortly after. In a 500 m long section of the Dortmund-Ems-Canal a newly developed innovative GCL was installed under water. The installed GCL was Bentofix® BZ 13-B, a double-layered composite GCL developed for an under water installation. Over the carrier geotextile is the natural sodium bentonite as sealing element, covered with a separation nonwoven geotextile, a sand ballast layer and the cover nonwoven geotextile. All layers are needle punched together creating a long-term resistant uniform shear strength transferring GCL. One main advantage: An under water installation in one process.

The function of this innovative product is easily described. The bentonite layer hydrates in contact with water and forms a uniform sealing gel with a hydraulic conductivity value of < 5 x 10 E-11 m/s. The sand ballast layer acts as a protection layer against the rip-rap revetment which are placed directly over the Bentofix® BZ 13-B. The otherwise needed hard to install and minimum 10 cm thick sand protection layer is therefore not necessary. The product and bentonite width is 4.85 m. The sand ballast width is 4.35 m. The overlapping width of 0.50 is impregnated with natural sodium bentonite which ensures that the overlap zone acts as an sealed area.

To ensure the proper installation of the GCL the contractor used GPS guided equipment. To monitor the performance of the innovative Bentofix® GCL BZ 13-B a control system under the GCL was installed which enabled the authority to register any unlikely leaks.