Case Study: Armormax® California Highway

Construction Date: Fall 2005

Location: Calaveras County, CA

Products: ArmorMax®

General Information

During the heavy rainy season in California’s Calaveras County, a steep cut 1:1 slope along Highway 26 became saturated, creating a shallow slope failure. Caltrans District 10 Maintenance, the department responsible for the repair, was tasked with repairing the slope quickly because of the threat of potential land slides to travellers as well as the negative environmental impact of sediment release into an adjacent sensitive waterway—the Mokelumne River.

Before the repair got underway, Caltrans identified a number of concerns that would have to be addressed and overcome throughout the repair. First, the failed slope is next to Highway 26 which meant Caltrans would possibly have to close one lane of the highway to perform the repairs. Additionally, Caltrans was not given purchasing rights for the right-of-way at the top of the slope, so it would not be able to chase the slope back into the hill, creating a gentler slope. It also found that providing permanent protection for the slope was critical as further slope erosion would endanger motorists and have a negative environmental impact.

Design & Construction

As preparations to repair the slope continued, Caltrans was confident it could find a solution to repair the slope without closing one lane of the highway or chasing the slope back into the hill, while providing permanent erosion control protection.

Two possible solutions were considered: ArmorMax®, an anchored reinforced vegetation system consisting of a high performance turf reinforcement mat (HPTRM) with earth percussion anchors, and rock slope protection. After further investigation of the slope, Caltrans concluded rock slope protection would not be possible due to the height (approximately 120 feet) and angle (approximately 45°) of the slope as well as the high cost. What’s more, Caltrans was really in favor of creating a natural looking environment—that’s difficult to do with rock protection.

Caltrans ultimately chose a vegetated solution, specifying ArmorMax®—the HPTRM was judged to be the strongest available with a tensile strength of 4,000 pounds—with earth percussion anchors. ArmorMax® was specified because of its low impact, required only handheld equipment for installation and provided an instantly attractive finish to the slope.

It also meant that there was no need to purchase additional right-of-way or close the lane of the highway, making it the most cost-effective option. They rejected other Turf Reinforcement Mats (TRMs) because of hydraulic performance, installation, durability, maintenance, and UV resistance issues.

“The HPTRM utilised in the ArmorMax® system is many times stronger than traditional turf reinforcement mats and is equipped to handle the most demanding erosion control applications,” says Brad Cooley with Propex Geosynthetics. “The outstanding UV resistance makes it the preferred TRM for severe applications that require outstanding strength and superior vegetation growth—and UV resistance was extremely important to Caltrans. They feared the angle of the slope as well as the low fertility of the decomposed granite soil wouldn’t allow for much vegetative cover—which you could see by the lack of vegetation on the hills to the left and right of the failed slope—leaving the mats exposed to the harsh California sun.”

Installation

To prepare the slope for the installation, Caltrans positioned five k-rails on the shoulder to keep motorists from entering the construction zone. Once the shoulder was secured, a five-man crew from Thunder Mountain Enterprises, Inc., of Sacramento, removed the failed soil at the bottom of the slope. Next, the team, with the help of repelling equipment, graded the slope with shovels and rakes. After the slope was graded, the entire slope was hydroseeded with a native seed mix and a bonded fiber matrix product provided by Mark Seeding, Inc.

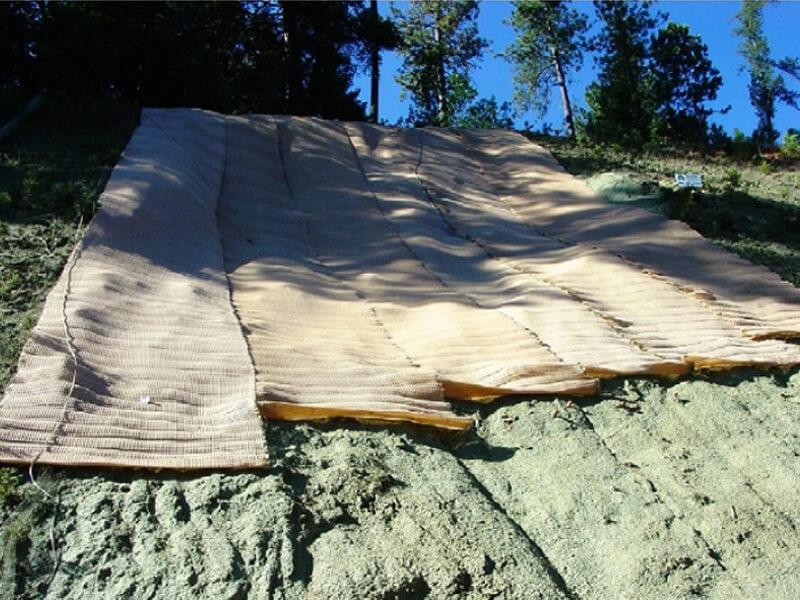

At the top of the slope, a 60-foot long anchor trench that was one-foot wide and one-foot deep was then constructed. After the trench was dug, the mat was anchored to the bottom of the trench and the team back-filled the trench with native soil from the top of the slope—then the team unrolled 1,500 yd2 of the HPTRM down the slope. The design called for earth percussion anchors with a 4.5-inch stainless steel tendon to be driven through the HPTRM on a checkerboard grid patterns at five feet centers.

“Conventional first generation stitch-bonded or fused monofilament TRMs could not have been anchored in this manner,” says Cooley. “The dimensional stability of stitch-bonded TRMs would be compromised by the penetration of the anchors.” According to James Chinchiolo of Soil Nail Launcher, Inc. (formerly of Thunder Mountain Enterprises), the team, using repelling equipment and a boom truck, employed a pneumatic air hammer to install the anchors, which helped secure the ArmorMax® to the decomposed granite soil and greatly accelerated the project’s construction.

“It wasn’t specified, but we also used a lot of pins to make sure the mats had intimate contact with the soil, preventing water from rushing down the slope between the ground and the mat, which would have washed the seed away. After ArmorMax® was anchored in the soil, the slope was hydroseeded with a compost layer that included the same native seed mix and bonded fiber matrix as well as a little bit of soil,” says Chinchiolo.

“From our perspective, the installation of the mat was really pretty easy for a number of reasons,” continues Chinchiolo. “We didn’t have to build a buttress or shut down a lane of the road, which would have been done if we were going with a rock slope protection application. And our equipment compliment was darn near nothing—all we needed were a couple of pneumatic hammers and a boom truck.”

Thunder Mountain completed the installation in the fall—just two short weeks after starting the repair work. Within a month after completion vegetation was already starting to emerge—the HPTRM trapped the morning dew, providing moisture for the seed germination during this particularly arid time of year—and six months after work was finished, the slope was 80% - 90% covered. The project was particularly successful due to the speed and simplicity of ArmorMax®’s system construction, the elimination of heavy equipment that would have been necessary to install the rock slope protection, and the rapid vegetative establishment properties of the HPTRM.

Results

Using ArmorMax® on the Highway 26 project proved to be an effective, economical, and technically sound permanent erosion control solution. The total cost of the slope repair came in at approximately $50,000; Propex Geosynthetics’ ArmorMax system was installed on this project at an approximate cost of just $22,500—or about $15/yd2. Not only was ArmorMax® more cost-effective than rock slope protection, it also saved Caltrans time and hassle by delivering a faster installation schedule which reduced the construction timeline.

In addition to these benefits, the mat offered Caltrans a solution that provided multiple environmental benefits in a very demanding area of California, including natural appearance, water cleansing and promotion of sediment capture. After the winter of 2006—six months after installation—Caltrans reported there was no sediment build-up in the ditch at the base of the hill as well as no impacts to the adjacent stream, which was crucial to maintaining its pristine condition. “I talked to Allan Shafer, Caltrans’ maintenance storm water coordinator, last summer, and he’s happy with the performance of ArmorMax®,” says Chinchiolo. “He said it’s done a great job keeping the sediment out of the Mokelumne River drain inlet, which was his primary concern.”