What is Landfill Live Expansion?

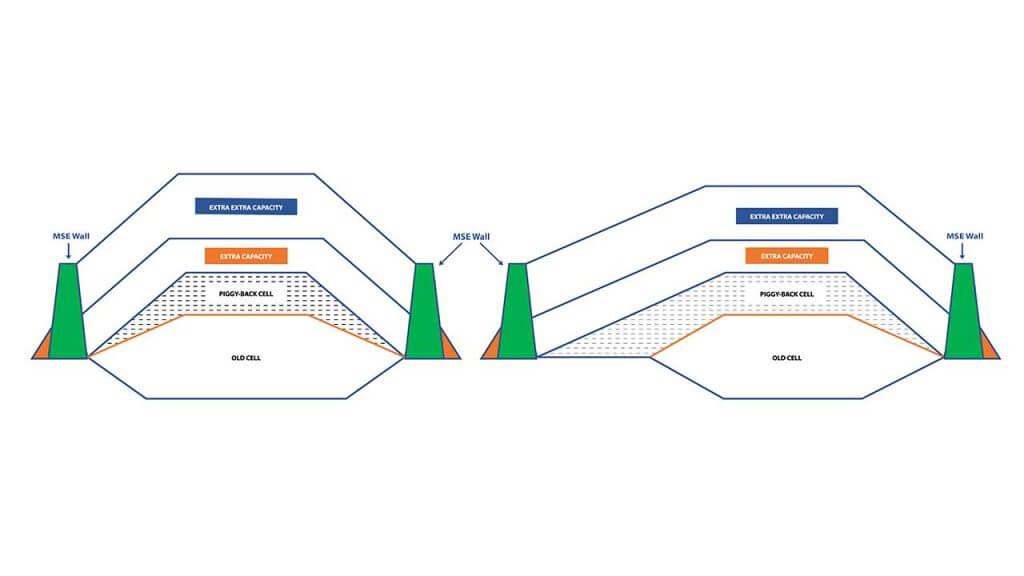

Landfill expansion can be either piggy-backing or live expansion. Piggy backing is actually building a new landfill above an existing one after it is capped. Live expansion is increasing the landfill capacity while under operation. It will allow the existing landfill to operate while the extension is happening. Live expansion increases the landfill capacity and operation life without the need of going into the closure process first. The most economic way of such expansions is using geogrid reinforced mechanically stabilised earth wall/berm (MSE wall/berm). This system and technology can be used for landfill expansions as well as construction of new landfills to increase the capacity and airspace without using more land.

More information about Landfill Live Expansion can be found here.

Erskine Park Landfill project

Issues and Challenges

Cleanaway’s Erskine Park Landfill airspace was forecasted to be exhausted late 2020. No other landfill assets were available in the NSW portfolio. Horizontal expansion was not an option, and conventional vertical expansion methods already applied. The landfill was situated at the site of an excavated volcanic diatreme in Western Sydney. Property boundaries constrain the lateral expansion of the landfill. The required design life was 100 years. A method was required which allowed the landfill to increase capacity and extend its operational life without the need for closure (known as live expansion).

Solution

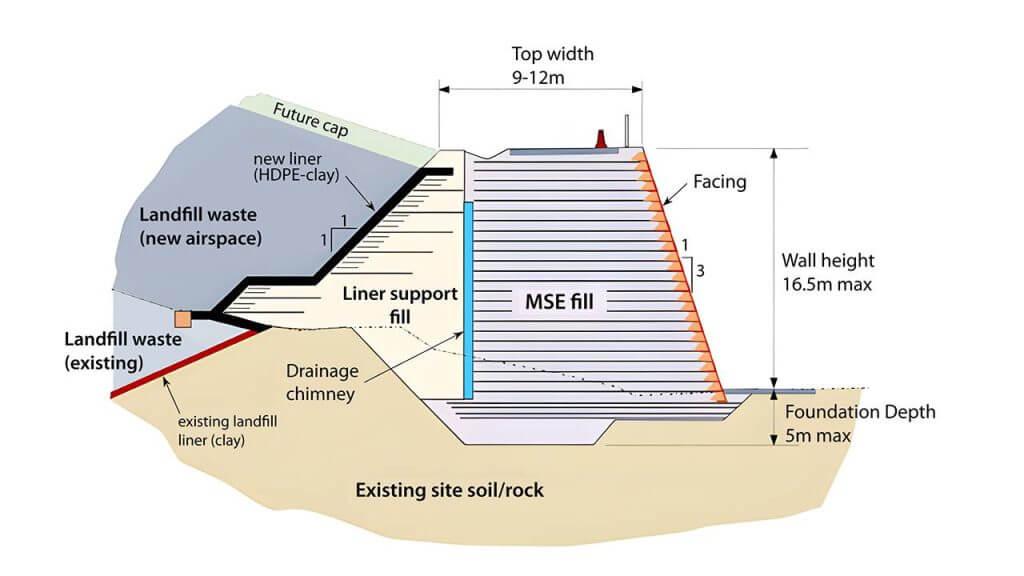

Following an optioneering assessment phase by WSP, the Terralink® MSE wire wall system comprising a geogrid retaining wall with steel mesh facing was assessed to be feasible and economically viable to increase available airspace for waste placement. The Terralink® MSE wall system comprises a geogrid retaining wall with steel mesh facing. This method, which is distinct from piggybacking, involves the construction of a geogrid reinforced mechanically stabilised earth wall or berm (MSE wall/berm), facilitating the expansion process during active landfill operations. The technique not only saves space but is also economically advantageous.

The MSE wall system was designed by WSP. Key design considerations for the MSE retaining wall included serviceability, settlement, design life and durability from exposure to adverse environments, foundation requirements, backfill quality requirements and construction costs.

Other considerations during the design included the durability of the structure and the visual appearance, given the scale of the structure. Pyramat ®75 High Performance TRM (HPTRM) with 100 years design life was used within the MSE wall at the facing behind the mesh, for additional long term durability requirements as well as provide a green surface and appearance.

To account for foundation variability, the wall was designed to accommodate the compression and consolidation of the founding materials to ensure it functioned effectively supporting the landfill lining system and maintained its structural integrity. AceGrid® geogrid and Secugrid® biaxial geogrid were also used to stabilise the soil in some parts of the foundation.

More information about project detailed design can be found here.

The Cleanaway’s Erskine Park Landfill in NSW, recognised as the "Great Wall of Sydney", showcases a pioneering approach to landfill expansion known as live expansion. This technology and approach were in line with Cleanaway’s Blueprint 2030 strategy, Blueprint 4 – Landfill Optimisation, which focuses on investing in new capacity to ensure that there is sufficient airspace at our existing landfill operations.

Global Synthetic’s technical and sales team were involved in this project from early stages including the feasibility study all the way to the construction and CQC technical support.

Features and Benefits

Erskine Park Landfill's live expansion, the first of its kind in Australia, features the country's largest landfill application of MSE technology—900 meters in length and over 16.5 meters high. The project, engineered by WSP and executed by Global Synthetics, has set a new standard in landfill engineering.

The MSE wall technology unlocked 430,000 cubic metres of airspace that was previously not available. This extends the operational life of Erskine Park Landfill by over three years and alleviates some of the pressure on Sydney’s landfill network.

“We have set a precedent for the Australian landfill industry. In a climate where fewer and fewer landfills are being approved, this technology opens up the opportunity to revitalise dormant assets or extend the life of assets heading towards closure.” says Cleanaway Landfill Manager Daniel Wright.

For its innovative MSE wall project, the landfill was awarded the ‘Outstanding Innovation, Project or Facility’ award at the 2023 Australian Landfill and Transfer Station Awards".

TERRALINK® MSE Wall - Erskine Park Video